The content is published under Creative Commons Attribution 4.0 International license.

Reviewed Article:

Variables and Assumptions in Modern Interpretation of Ancient Spinning Technique and Technology Through Archaeological Experimentation

This paper takes the form of a critical analysis of archaeological experiments using spinning tools. The archaeological experiments regarding whorl weight and wool spinning of the Tools and Textiles – Texts and Contexts project, through the Danish National Research Foundation’s Centre for Textile Research, are examined with respect to a number of variables. These variables include the experience of the technicians, the details of the reconstructed spindles and technical aspects of preparation and spinning methods. The variables and their implications are insufficiently addressed in the technical reports of the experiments, and further consideration and elucidation would enhance the interpretation of experimental results.

Archaeological experimentation of this type would also benefit from the incorporation of ethnographic observation to provide contextual information and comparative behavioural data. The assumptions inherent in modern approaches to fibre technology and their influence on archaeological experimentation are considered, with a view toward encouraging a more self-conscious approach to the analysis of fibre experiments.

Introduction: spinning experiments

A series of archaeological experiments were conducted in 2005 and 2006 as part of the Tools and Textiles – Texts and Contexts (TTTC) project through the Danish National Research Foundation’s Centre for Textile Research (CTR) in Copenhagen. This work is highly significant to the study of textile technology because there are very few institutions with a focus on historical textile research. The focus of the current paper is on the wool-spinning portions of these experiments. This analysis aims to highlight variables and technical details that require further discussion and clarification, with the purpose of encouraging development of the experimental method.

The focus of this paper is deliberately precise, concentrating exclusively on one set of a series of specific experiments. There are several reasons for this focus. In the literature of textile studies, very little attention is paid to spinning, as compared to weaving. Spinning is perceived as a generic step in textile production and few scholars are qualified to examine the subtleties and variables inherent in this stage, which is itself a complex process with definitive impact on the finished product. As a result, spinning and its various components are often glossed over, in the interest of moving on to the ostensibly more complex technology of weaving (Landi, 1998: 11; Boersma et al., 2007: 13).

The experiments discussed here give importance to spinning, emphasising the role of whorl weight, which significantly adds to the body of knowledge applicable to archaeological finds. In recognition of the importance and prominence of the CTR program and the potential for continuation of informative textile studies in archaeology, it is necessary to be as thorough as possible in the approach to understanding spinning and its role in textile production. Thus the specificity of this article draws attention to the relevance of seemingly minor or negligible details in the conducting of spinning experiments, with the goal of elucidating variables and important considerations for the interpretation of data produced by such experiments.

Another reason for analysis of these experiments in particular is the conclusive status that published data acquires. Production rates for ancient cloth and parameters for spindle whorl weight deduced from the experiments continue to be cited as factual (Mårtensson et al., 2009: 393; Meyers, 2013: 257; Andersson et al., 2008). Without an examination of the interpretation of that data, the numbers may not reliably be used as a foundation for archaeological studies.

Technical reports for part 1 and part 2.2 Whorl or bead? of the TTTC project explain experiments involving spinning with replicas of ancient spindle whorls. The main questions for part 1 were: how do individual spinners affect the spun yarn and can whorls weighing less than 10 g function as spindle whorls? (Mårtensson et al., 2006a: 4)The question addressed in part 2.2 was how a 4 g whorl functions as a spindle whorl for spinning weaving yarn, to be woven on a warp-weighted loom (Mårtensson et al., 2006b: 4). The studies have effectively shown that a whorl as light as 8 g, or even 4 g, can be used to spin yarn suitable for weaving on a warp-weighted loom, which is a significant point regarding archaeological finds. However, other results are less conclusive, given the limitations of the sampling and the breadth of variables that are left unaddressed.

For example, one of the main conclusions is that the tool is more of a factor than the person using it, in determining what type of yarn is spun (Mårtensson et al., 2006a: 14; Andersson et al., 2008; Mårtensson et al., 2009: 165). Detailed analysis of the experiments will demonstrate that this assertion may not be the obvious interpretation of the data, once all the variables and assumptions are taken into account.

Additionally, in the TTTC reports emphasis is placed on ease of use and the time required for tasks. Such factors cannot be measured as numerical data, but must incorporate a range of considerations, affected by the individual and cultural influences involved in the entire process of spinning, both in the experimental setting and in living textile-producing cultures. The interpretation of the experiments would be more complete with information collected from observation of handspinning cultures. Such information could also help inform the structure of future experiments.

Living traditions as an aid to modern interpretation

In assessing numerous aspects of the spinning experiments, it is helpful to refer to living textile traditions and the trends of tool usage that are demonstrated by indigenous spinners. Such people have handspinning embedded in their lives as an everyday technique and while this cannot show us exactly how things were done in a specific historical culture, ethnographic observation can demonstrate how the technical skills fit into daily life and society (Wild, 1970; Lemonnier, 1993; Hudson, 2008a). This is extremely useful in interpreting patterns of tool use and production methods, in addition to the role of ‘efficiency’ in textile production.

There are innumerable assumptions made by modern practitioners when approaching the re-enactment of a historical craft, many of which may be unconscious and therefore unconsidered. Craftspeople work according to the way they were taught and many contemporary handspinning teachers have taken up the craft independently of any tradition. They teach in a manner influenced by current ideas about yarn and desired results, which differ from ancient production needs; therefore, the technique is bound to be different. For this reason, it makes sense to take cues from textile-producing cultures that continue to practice pre-industrial methods, rather than assuming a universality to a method that is taught in modern post-industrial societies as a non-essential craft (Franquemont, 2009). The methods of current textile-producing cultures will reflect similar priorities as ancient cultures, in that the handspinning will be directed by the goal of a specific type of yarn, usually for weaving (Hilden, 2010), and the work of spinning will also be integrated into the daily routine and general lifestyle of the spinners (Hudson, 2008a; Franquemont, 2009: 7).

It is also important to bear in mind that the skills and use patterns of production handspinners will differ greatly from those of sporadic spinners or those who have recently acquired the skills (Tiedemann and Jakes, 2006). These points are relevant to each of the stages of experimentation and interpretation in any spinning experiment.

To emphasise the benefit of ethnographic observation, several online videos of traditional handspinners have been included among the references for this paper, cited where they are relevant to the discussion. Living handspinning communities, both traditional and modern, offer a wealth of knowledge that can be a beneficial resource for academic craft studies (Ciszuk, 2007).

Spinning experience within the study sample: the relevance of textile background

Given the divergence of handspinning skills across and within cultures, an inquiry into the background of the experimental spinners is necessary. The TTTC experiments are carried out by two “experienced textile technicians,” who are introduced by name, country and profession, but without further information regarding their spinning experience (Mårtensson et al., 2006a: 3). Two individuals is an extremely small study sample and while following the CTR policy of using “at least two” craftspeople to conduct an experiment (Mårtensson et al., 2006a: 3; Mårtensson et al., 2009: 379), it does not seem sufficient to test differences between individuals as opposed to tools.

There is reference to the importance of selecting people with different textile backgrounds (Mårtensson et al., 2006a), but since there is no detailed explanation of the respective textile backgrounds, the suitability of the study group is not demonstrated. One technician is from Denmark and one from Sweden, but the report does not explain where and from whom the women learned to spin, which is highly relevant to their style, tool familiarity and assumptions about correct methods (Minar, 2000: 94). For example, if either of them learned to spin from a contemporary professional teacher, from the Internet, or in another international situation, the method of spinning may be very generalised (Franquemont, 2009). This will differ from the methods of a Danish or Swedish grandmother passing on a continuous tradition from her own family. People tend to spin according to the way they were taught (Minar, 2000: 94), so this factor is very important when considering the textile background of an experimental technician.

The level of experience of the spinners is also not defined. If they are accustomed to using a spindle and have spun in this manner for many years, this will affect the ease with which they take up the reconstructed Bronze Age spindles. Conversely, if they habitually spin with a wheel, or have learned spindle spinning within the last few years, it will be more challenging to be productive using the experimental tools (Tiedemann and Jakes, 2006: 303). For this reason, the technicians’ familiarity with the specific tool being tested has an influence on how results may be interpreted and should be stated as part of the introduction. A later publication refers to the technicians’ years of experience (Andersson Strand, 2012). Perhaps this information will be included in the forthcoming book on the CTR studies (Andersson Strand and Nosch, forthcoming).

The TTTC Part 1 report mentions “one initial test” of the spindle, to allow the spinners to get comfortable using it (Mårtensson et al., 2006a: 7). The duration of this test period is not mentioned, but it is the first time the spinners have worked with the experimental spindles. As an experiment to test whether the 8 g or 4 g spindle works, this is not a problem. However, as a basis for calculating production rates and efficiency of the tools of various weights, it is problematic to use craftspeople who are unaccustomed to the specific tools and are given only a short period of practice before the experiment.

In a given textile-producing culture, the techniques of spinning are introduced at a very young age and those who spin yarn for production weaving will have spent much of their lives using the tools on a daily basis (Meisch et al., 2003; Callañaupa Alvarez, 2007; Hudson, 2008b; Franquemont, 2009: 9). There can be no comparison between the production level of people who are raised in a living textile tradition, spinning from childhood, with those who have learned spinning as an adult in a manner that is not essential to their livelihood (Tiedemann and Jakes, 2006). To imply that the amount of yarn spun in a given period of time by the experimental technicians can be interpreted as production rates of ancient cultures (Andersson et al., 2008: 173; Andersson Strand, 2012: 34) overlooks these factors.

The report would potentially be enhanced by a comparison with the normal production rate of the experimental spinners working with their own accustomed tools. No indication of how their skills with these spindles compare to their skills with other types of spindles is given, which would provide a sense of perspective, within the study group.

Fibre preparation

Before the wool can be spun, it must be sorted, cleaned and prepared to some extent. There is a wide spectrum of fibre preparation processes, from doing almost nothing, to carefully aligning all of the fibres by hand or using combs (Meisch et al., 2003; Hudson, 2008b; Hilden, 2010: 126). The method of fibre preparation can have a significant influence on the spinning of the yarn (Amos, 2001: 63; Bakriges, 2010: 67; Andersson Strand, 2012: 31), so it is an important factor in textile production. The traditions of a given textile culture will include specific methods of fibre preparation, but unless indicative tools survive, it is hard to deduce the methods of ancient cultures (Wild, 1970: 24).

The preparation of the fibre affects the ease and manner of drafting and also influences the type of yarn produced. In English, a distinction is made between woolen and worsted, in terms of fibre preparation, drafting method and spun yarn (Ross, 1986: 17; Franquemont, 2009: 66). A woolen preparation, with fibres oriented in different directions, is more suited to a ‘long-draw’ drafting method with the twist entering into the fibres as the hand pulls back (Bakriges, 2010; Franquemont, 2009: 66). Woolen preparation and drafting traps more air in the yarn, creating a lofty, springy yarn with increased elasticity and the capacity to blend or mesh, visually and physically, with neighbouring yarns in the finished weaving (Ross, 1986). Worsted preparation aligns the fibres parallel to one another and is drafted in a manner that controls the twist, with hands held close together. This controlled method produces a more dense yarn with a smooth surface, which provides strength and gives definition to the finished weaving pattern, with less elasticity (Baines, 1977: 32; Ross, 1986: 18; Franquemont, 2009: 68). While these terms are English, the qualities of fibre preparation and spinning technique represented by them are encountered in textile traditions all over the world, so understanding this distinction is relevant to any study of hand spinning history (Hudson, 2008b; Meisch et al., 2003: 84).

The method of fibre preparation for the TTTC experiment is chosen and justified and this would seem to eliminate the role of fibre preparation as a variable. However, if the historical method is unknown (Mårtensson et al., 2006a: 5), it would be more informative to test multiple methods through the spinning stage to determine the influence of this variable. The influence of the given method of fibre preparation is not measured, neglecting the importance of fibre preparation as a variable affecting all other stages of spinning.

It is also important to note how many assumptions and choices are coming into play in the chosen preparation method. For example, when the fibres are sorted, they are slightly opened by hand and laid out, avoiding placing the locks “upside-down” on top of one another (Mårtensson et al., 2006a: 4). The reason for this and its importance to subsequent preparation is not explained and it is evident that even at this stage certain choices are being made based on culturally acquired technological beliefs. In this respect, the fibre preparation process needs to be more self-conscious and more thoroughly explained, documented and demonstrated. The myriad steps preceding the actual spinning of the fibre have both cultural and technological relevance to the process and to the finished product. While there is discussion of the method of preparation, the terminology is unclear, and comparisons to known methods are not made. The effect of fibre preparation on the spinning process is emphasised (Mårtensson et al., 2006b: 5), but this aspect of the experiment is not addressed thoroughly, showing demonstrable results.

In traditional textile producing cultures, various methods of preparation are used, sometimes differing between yarn spun for warp versus weft, while the skill of the spinner is inherent in the approach to fibre preparation. This is especially evident in traditions using very little preparation and spinning more directly from the fleece (Callañaupa Alvarez, 2007; Hilden, 2010). The comments in TTTC reports emphasise the influence of fibre preparation, but in a way that separates it from spinning skill, whereas ethnographic observation shows the integrated quality of fibre preparation and spinning (Meisch et al., 2003; Hudson, 2008a).

Spindle specifications

The TTTC experiment was designed to explore a certain weight and type of whorl, modelled on excavated whorls from Nichoria (Mårtensson et al., 2006a: 6). The experimental whorls were carefully made and selected, in accordance with the CTR guideline that tools must be “precise copies of archaeological artefacts” (Mårtensson et al., 2006a: 3). However, there is more to a spindle than just a whorl, and the shaft must be equally carefully considered.

The size, shape and length of the spindle shaft are significant factors that can indicate the manner in which the spindle is used. Unfortunately shafts are rarely preserved, being most often made of organic materials (Barber, 1991: 51). It is therefore understandable that the shaft of the experimental spindles had to be improvised. Certain clues may be provided, such as the interior profile of the whorl. For example, if the interior of the whorl is narrower at one end, it is clear that the whorl would be fitted to the shaft in such a way that gravity and friction keep it in place (Barber, 1991: 52; Gleba, 2008: 108). Regional historical depictions and ethnographic observation can also be considered. While one cannot know the Bronze Age spindle style, deductions can be made from this kind of surrounding information. The only reference given for the chosen shaft design is a previous experiment in a publication referring to the Late Iron Age, with no further information (Mårtensson et al., 2006a: 6).

There are photos of the whorls and of the spindles with a scale, and in the case of the 4 g whorl, a drawing shows the interior profile to be straight and not tapered (Mårtensson et al., 2006b: 4).Based on the photos, the shafts for the 18 g and 8 g spindles appear to be 24 cm and 14 cm respectively. The 4 g whorl is used with a 14 cm shaft. (Mårtensson et al., 2006a: 7; Mårtensson et al., 2006b: 4). There is no explanation given for the choice of length and variation in length based on whorl size. The length of the spindle will affect its ease of use, so it is an important variable. For instance, if the lighter whorl had the same length shaft as the heavier whorl, the spinners may have noticed a difference in handling the spindle.

It is important to consider that even with a given whorl shape and weight, there are quite a few different ways to design and use a spindle (See Figure 1) (Barber, 1991: 43, 62). The experimental whorls are placed low on the shafts, about 4 cm from the bottom, and the shafts taper toward the top, where there is a hook carved into the wood. The use of a hook is a significant choice that should be documented and discussed. Low-whorl spindles do not require a hook to attach the yarn: the spinner can make a half-hitch at the top of the shaft to allow the spindle to hang while spinning. This is a typical practice in Peru and Bolivia, and can be observed elsewhere (Franquemont, 2009; galatbazaar, 2012). The assumption that the whorl is low on the shaft is consistent with regional spinning technique historically (Barber, 1991: 53, 64), but the use of a hook cannot be assumed.

Spinning technique

While the experiment aimed to allow the spinners to influence the outcome individually, the specific restrictions chosen, i.e. to spin seated with a suspended spinning technique (Mårtensson et al., 2006a: 7), seem to limit the type of individual choices that naturally occur. Indigenous spinners tend to be productive precisely because their work accompanies them throughout the day, so spinning can be accomplished regardless of location (Callañaupa Alvarez, 2007: 50; ProjectoSaberFazer, 2011). This mobility leads to a certain flexibility of style, with the spinner using the spindle supported if seated, suspended if standing and possibly making use of a distaff to hold the fibre (Meisch et al., 2003; Hudson, 2010).

Historical and contemporary documentation from Europe shows spindles held in the hand and turned in a manner that is semi-suspended and occasionally supported, often with a distaff holding the fibre (oficinadofio, 2009; BosnianReality, 2012; Là em tempo real, 2012; DiAlessandri, 2013). Therefore, to use exclusively a seated, suspended spinning style for the TTTC experiments, with no mention of a distaff, does not address the potential scope of ancient spinning technique (Andersson Strand, 2012: 32)(See Figure 2 - 4)

Another factor affecting the way spinners create yarn is the intended purpose of the yarn. Requirements such as thickness, density and amount of twist necessary for a desired finished product, inform the spinning techniques of handspinners, from ancient times to the present (Wild, 1970: 37; Franquemont, 2009: 65). When spinning for weaving, the warp yarns must be particularly strong, to withstand the tension of the loom, whereas weft yarns can be more lofty or loosely spun (Meisch et al., 2003: 89; Callañaupa Alvarez, 2007: 50; Hilden, 2010).

The TTTC Part 1 report states that “we did not decide in advance how exactly to spin our thread.” (Mårtensson et al., 2006a: 7) It is unclear whether this refers to technique, or to parameters of the spun yarn. With regard to the latter, the statement is problematic because it appears that both spinners know at the outset that they are spinning singles for weaving on a warp-weighted loom. This is confirmed by the next paragraph’s reference to the yarn being strong enough for a warp. So the type of yarn being spun is decided at the outset, based presumably on the spinners’ own standards for weaving yarn. If the allowance for individual variability is meant to refer to technique, it would be helpful at this stage for each spinner to make private notes about her intentions, so the goals and decisions could be examined objectively.

The two spinners had the same type of yarn as a goal and the same fibre prep, and were restricted in their posture and spindle-using technique, so the variable left to them is drafting.

Drafting

Drafting is the manner of attenuating the fibre while spinning with the spindle. It is the aspect of the spinning process that incorporates the skill and expertise of the spinner to influence the yarn, as it is being spun. Drafting method and fibre preparation are closely related, and this is the stage at which spinners make choices and modifications based on the intended use of the yarn (Bakriges, 2010).

However, the TTTC experiment does not refer to drafting per se, or elucidate the relationship between the spinners’ methods and the fibre preparation. There is mention of how the fibre is held in the hand (Mårtensson et al., 2006a: 7) and of needing to “work a lot with the hands” (Mårtensson et al., 2006b: 6; Andersson et al., 2008: 173) to manage the fibre on the lighter spindle, but these are not technically informative. The spinners’ own notes would be beneficial, with some attention to internationally used spinning terminology, such as worsted and woolen, mentioned above, and further graphic documentation of the techniques used. Given that this is the main variable between the two spinners, it could be more fully documented. This would be useful in demonstrating the difference or similarity of the spinning techniques between individuals.

Counting

Rather than making notes on drafting technique, the spinners noted the number of “twists” given to the spindle during a certain length of yarn (Mårtensson et al., 2006a: 7). In a living textile producing culture, spinners are not likely to count an action, but rather to rely on the feel of the yarn, developing an intuition for the right amount of twist (Franquemont, 2009: 83-84). Counting treadling was introduced as a wheel spinning guideline by Mabel Ross (1986). Modern spinners who have been trained in this manner may give importance to counting as a way of measuring the twist added to the yarn, but for people who grow up with spinning as a daily activity, the process is much more intuitive. With spindles, the force given to the twist is highly variable. Depending on the thickness of the spindle shaft and the spinner’s method of putting the spindle in motion (Franquemont, 2009), one “twist” may have a lot more energy than another, so it is not a reliable measure of work.

If such a count is deemed important to the experiment, it would be more natural and imitative of traditional textile production to allow the spinners to develop their own rhythm and have an observer collect the numerical data, while remembering that there is variability between the “twists,” in terms of force and effectiveness. While this variability is acknowledged in the TTTC report, the rationale for counting the twists given to the spindle is not explained. It is unclear how that information adds to the interpretation of the yarn and spinning process.

Full spindle?

The point at which a spindle is ‘full’ is another unexamined variable in the spinning experiment. This may be the most important factor, due to its implications regarding the production rate data. The spindle was considered full when “the weight of the threads affected the rotation of the spindle negatively.” (Mårtensson et al., 2006a: 7) This highlights an additional skill involved in spinning yarn: winding the spun yarn onto the spindle shaft. The spun yarn stored on the spindle is called the cop and building a firm and stable cop with a skilful winding technique, enables a spinner to spin more yarn before the weight of the yarn interferes with the rotation of the spindle (Franquemont, 2009: 86,87). It is also a practical consideration for the portability of the spinning task, because a stable cop will not become loose and fall off the spindle. For these reasons, a production spinner would develop this skill along with the other steps of making yarn. In the interest of time management, she would fill each spindle as full as possible before stopping the work to wind off the yarn (Franquemont, 2009: 87).

During the CTR experiment, the average weight of yarn on a full spindle and the percentage of the weight of the empty spindle was as shown in Table 1.

Spindle weight | Avg. yarn weight AB | Avg. yarn weight LM | Percentage of spindle wt. AB | Percentage of spindle wt. LM |

8 g | 2.4 g | 2.7 g | 30% | 33% |

18 g | 4.3 g | 5.1 g | 24% | 28% |

4 g | 2.0 g | 2.4 g | 50% | 60% |

Table 1. Average yarn weight for full spindles for each spinner, with percentage of empty spindle weight. (Mårtensson et al., 2006a: 10; Mårtensson et al., 2006b: 6)

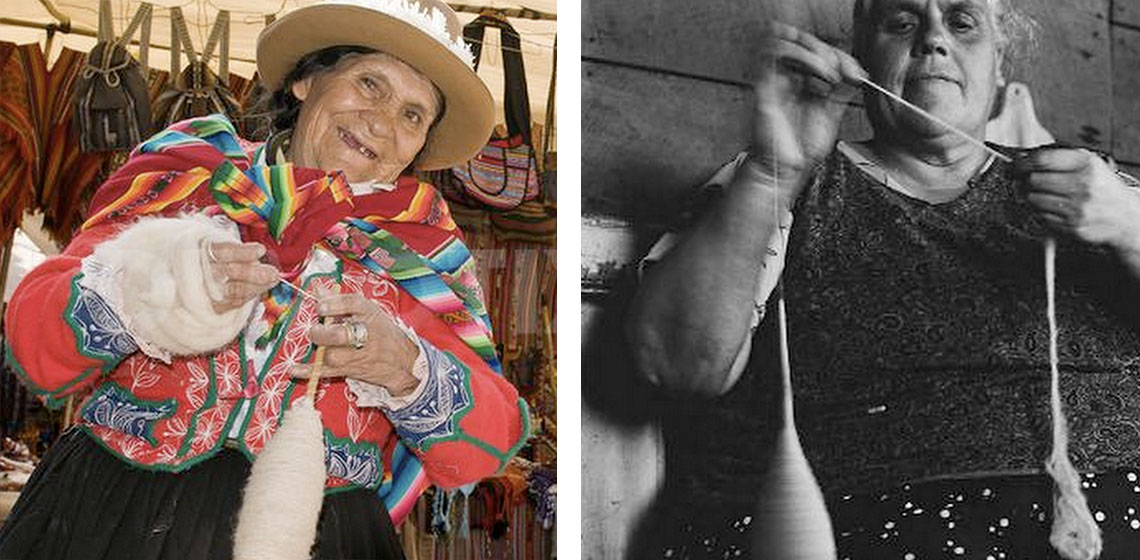

The percentages are surprisingly low, when compared to general observed and documented tendencies (Kania, 2009). Spinners tend to fill a spindle with yarn that is several times the weight of the empty spindle (See Figure 5). This practice is clearly seen in imagery and documentation of traditional spinning around the world (See Figure 6) (Meisch et al., 2003: 76; Callañaupa Alvarez, 2007: 49; Brooks, 2011). It is also demonstrated by modern spinners without a long tradition behind them.

In an experiment conducted by Katrin Kania (2009; forthcoming), fourteen spinners, described as ‘experienced hobby spinners,’ used three different whorl weights for an hour at a time. Given that these spinners stopped after one hour, without considering the spindles full, the weight of yarn on each spindle at the end of the session is revealing (See Table 2)

Spindle weight | Average yarn weight on spindle | Percentage of empty spindle weight |

5 g | 8.8 g | 176% |

15 g | 10.3 g | 68% |

52 g | 11.4 g | 21% |

Table 2. Average yarn weights and percentage of spindle weight for yarn spun in Kania's experiment. (Kania, 2009)

While the spinners in Kania’s experiment were not familiar with or completely comfortable spinning with the given spindles, especially the heaviest one (Kania, 2009), they did not seem to be limited by the amount of yarn stored on the spindle, but by production speed. For the spindles of comparable weight to the TTTC experiment, the spinners in Kania’s experiment wound on two to three times the amount of yarn within the hour, without reaching the ‘full spindle’ point. For this experiment, spinners were using different fibres in addition to different spindles, so there was a variety of issues regarding workability, with none of the spinners using an accustomed spindle weight and fibre the whole time (Kania, 2009). In this sense, the spinners of Kania’s experiment did not have any particular advantage over those of the TTTC experiment.

The discrepancy between spindles designated as ‘full’ in the TTTC experiment and those observed elsewhere calls into question not only the production rates deduced from this experiment, but also the assertion that the tool rather than the spinner influences the outcome of the yarn (Mårtensson et al., 2006a: 14; Andersson et al., 2008). Since both the production rates and the predominant role of the tool continue to be cited (Andersson et al., 2009: 165; Andersson Strand, 2012: 33; Meyers, 2013: 257), it is important to note the lack of certainty inherent in the limitations of these experiments.

Conclusion: beyond whorl weight

In summary, while archaeological experiments exploring ancient textile tools are extremely important to the understanding of textile production in ancient societies (Andersson Strand et al., 2010: 163), caution must be exercised in drawing conclusions from such experiments. Full acknowledgement of the limitations, variables and choices involved in the structure of the experiment is essential to proper interpretation of any data produced.

Given the absence of an established body of academic research focused on spinning, there are inherent difficulties in setting up effective experimentation. Observation of living handspinning communities, with textile tools in productive contexts, could be incorporated as an aid to archaeological experimentation. Certain points of practice are known only to practitioners and those who live in textile producing communities will bring a different perspective than craftspeople unconnected to a certain tradition. The presence of living handspinning communities should not be ignored. Input from craft practitioners could widen study samples, better enabling comparisons of people, tools and technique. Reference to documented practices of living textile-producing cultures would add a valuable perspective on experimental processes and results.

The main variables in these experiments must be thoroughly noted and documented, in order to give a clear presentation of the circumstances of data collection. In the case of spinning experiments, such variables include the experience of the spinners, the details of fibre preparation and spinning technique, the specifications of the tools and the manner of assessing evaluative factors, both numerical and subjective.

It is necessary to remember that the experiment participants’ background and experience with the tools and techniques used in a study, influence interpretation of the results. Relevant details must therefore be carefully considered and included in the documentation. A self-conscious analysis of experimental conditions and decision-making would greatly enhance the data and enable more productive interpretation, not only in the studies discussed here, but in future textile-related archaeological experiments.

Bibliography

AMOS A. (2001) Big Book of Handspinning, Loveland, Colorado: Interweave Press LLC.

ANDERSSON E, FELLUCA E, NOSCH M-LB, et al. (2009) New Perspectives on Bronze Age Textile Production in the Eastern Mediterranean: The first results with Elba as a pilot study. In: Matthiae P, Pinnock F, Nigro L, et al. (eds) Proceedings of the 6th International Congress of the Archaeology of the Ancient Near East. Wiesbaden: Harrassowitz, 159-176.

ANDERSSON E, MÅRTENSSON L, NOSCH M-LB, et al. (2008) New Research on Bronze Age Textile Production. Bulletin of the Institute of Classical Studies 51: 171-174.

ANDERSSON STRAND E. (2012) The Textile Chaîne Opératoire: Using a multidisciplinary approach to textile archaeology with a focus on the Ancient Near East. Paléorient 38: 21-40.

vANDERSSON STRAND E, FREI KM, GLEBA M, et al. (2010) Old Textiles - New Possibilities. European Journal of Archaeology 13: 149 - 173.

ANDERSSON STRAND E and NOSCH M-L. (forthcoming) Tools, Textiles and Contexts. Investigations of Textile Production in the Bronze Age Eastern Mediterranean, Oxford: Oxbow Books.

BAINES P. (1977) Spinning Wheels, Spinners and Spinning, New York: Charles Scribner's Sons.

BAKRIGES J. (2010) Drafting Techniques: The long and short of it. Spin-Off 34: 64-67.

BARBER EW. (1991) Prehistoric Textiles: The Development of Cloth in the Neolithic and Bronze Ages, with Special Reference to the Aegean, Princeton, N.J.: Princeton University Press.

BOERSMA F, BROKER AW and VAN DEN BERG S. (2007) Unravelling Textiles - a handbook for the preservation of textile collections, London: Archetype.

BOSNIANREALITY. (2012) Hand Spinning Wool, Bosnia, Real Work, Withouth Efforts, http://www.youtube.com/watch?v=1R03D_QWVdc

Accessed 25 April, 2013.

BROOKS B. (2011) Old lady spinning wool with distaff in Breb, Romania.

http://www.youtube.com/watch?v=ShSIOF0o5js

Accessed 25 April 2013.

CALLAÑAUPA ALVAREZ N. (2007) Weaving in the Peruvian Highlands: Dreaming Patterns, Weaving Memories, Cusco, Peru: Center de Textiles Traditionales del Cusco.

CISZUK M. (2007) The Academic Craftsman - A Discussion on Knowledge of Craft in Textile Research. In: Gillis C and Nosch M-LB (eds) Ancient Textiles: Production, Craft, and Society - Proceedings of the first conference on ancient textiles held at Lund, Sweden and Copenhagen, Denmark on March 19-23, 2003. Oxford: Oxbow Books.

DIALESSANDRI C. (2013) Research and Documenting How They Spun. 15thcenturyspinning. http://15thcenturyspinning.wordpress.com/category/research/medieval-images/

Accessed 16/3/2013.

FRANQUEMONT A. (2009) Respect the Spindle, Colorado: Interweave Press.

GALATBAZAAR. (2012) Qashqai woman is spinning wool.

http://www.youtube.com/watch?v=hu-z07GA0HE&feature=youtu.be

Accessed 25 April, 2013.

GLEBA M. (2008) Textile Production in Pre-Roman Italy, Oxford: Oxbow Books.

HILDEN JT. (2010) Bedouin Weaving of Saudi Arabia and its Neighbours, London: Arabian Publishing Ltd.

HUDSON T. (2008a) Handspinning for Traditional Garments in Ladakh. Textiles as Cultural Expressions: Proceedings of the 11th Biennial Symposium of the Textile Society of America, September 24–27, 2008, Honolulu, Hawaii. Digital Commons:

http://digitalcommons.unl.edu/tsaconf/247/.

HUDSON T. (2008b) Spinning in the Himalayas. Spin-Off 32: 70-73.

HUDSON T. (2010) Bedouin in the Big City. Spin-Off 36: 48-51.

KANIA K. (2009) Spinning Experiment.

http://www.textileforum.org/

Accessed 23 March 2013.

KANIA K. (forthcoming) Soft Yarns, Hard Facts? Evaluating the results of a large scale hand-spinning experiment. Archaeological and Anthropological Sciences.

LÀ EM TEMPO REAL. (2012) D. Avelina fia com fuso apoiado,

http://vimeo.com/39434192

Accessed 25 April, 2013.

LANDI S. (1998) The Textile Conservator's Manual, London and New York: Routledge.

LEMONNIER P. (1993) Introduction. In: Lemonnier P (ed) Technological Choices: Transformation in material cultures since the Neolithic. London and New York: Routledge, 1-35.

MÅRTENSSON L, ANDERSSON E, NOSCH M-LB, et al. (2006a) Technical Report: Experimental Archaeology Part 1, 2005-2006. Tools and Textiles - Texts and Contexts Research Programme. Copenhagen: The Danish National Research Foundation's Centre for Textile Research (CTR).

MÅRTENSSON L, ANDERSSON E, NOSCH M-LB, et al. (2006b) Technical Report: Experimental Archaeology Part 2:2, Whorl or Bead? 2006. Tools and Textiles - Texts and Contexts Research Programme. Copenhagen: The Danish National Research Foundation's Centre for Textile Research (CTR).

MÅRTENSSON L, NOSCH M-LB and ANDERSSON STRAND E. (2009) Shape of Things: Understanding a Loom Weight. Oxford Journal of Archaeology 28: 373-398.

MEISCH LA, MILLER LM and ROWE AP. (2003) Spinning in Highland Ecuador. Textile Museum Journal: 76-97.

MEYERS GE. (2013) Woman and the Production of Ceremonail Textiles: A Reevaluation of Ceramic Textile Tools in Etrusco-Italic Sanctuaries. American Journal of Archaeology 117: 247-274.

MINAR CJ. (2000) Spinning and Plying: Anthropological Directions. In: Drooker PB and Webster LD (eds) Beyond Cloth and Cordage: Archaeological Textile Research in the Americas. Salt Lake City: University of Utah Press, 85-97.

OFICINADOFIO. (2009) Portuguese spindle.

http://www.youtube.com/watch?v=536xdbY-RJQ&lr=1

Accessed 25 April, 2013.

PROJECTOSABERFAZER. (2011) FIar com a D. Benta/ Spinning with D. Benta, http://www.youtube.com/watch?v=XexpKCxWOvo

Accessed 25 April 2013.