The content is published under Creative Commons Attribution 4.0 International license.

Reviewed Article:

Traction Trebuchet

The trebuchet, in all its forms, was very much in vogue in the reenactment and research community in the 1980s and 1990s. Several museums around the world have also built their own, with Middelaldercenteret in Nykøbing Falster in Denmark as one of the first modern examples of counterweight trebuchet (Hansen, 1989). Despite the multitude of builds, very little has been published about the process. When it comes to the traction machines, the authors are only aware of Tarver’s influential article (1995). From the historical perspective, Paul Chevedden (1998; 2000), amongst others, brought focus to the traction-based version of the machine, which is more commonly considered as an introductory note of the more awe-inspiring counterweight. At the Tower of London, a traction trebuchet clearly modelled on counterweight machines uses a pulling crew of about 4 people, throwing across the grass along the length of the outer walls (This seems to be their standard number, based on a range of YouTube videos taken by members of the public). This is the beginning of our work to change this state of the evidence of traction trebuchets, and attempt to see what the results of our experiments can do to help understand the physical realities of traction trebuchets at war. While those who specialize in traction trebuchets often have some tactical knowledge of its attributes, many historians of siege warfare more generally rely heavily on historical assumptions that do not necessarily stand up to critical evaluation. “While somewhat simpler to construct than its ancient predecessor, the logistical requirements of the traction trebuchet were just as great or even greater, and it needed even more trained crews and engineers to operate effectively, as well as a large number of expert craftsmen.” is only the most recent statement by Petersen (2013, p.409) of commonly accepted attributes. This is primarily accurate for traction trebuchet based on counterweight designs, principles and purposes. In this paper, we aim to illustrate why this is, in our experience, an inaccurate view of the smaller scale machines.

Tigna parant, quorum calibis dens summa peragrat,

Machina quo citius Danum quisset terebrari.

Conficiunt longis aeque lignis geminatis

Mangana quae proprio vulgi libitu vocitantur;

Saxa quibus jaciunt ingentia, sed jaulando

Allidunt humiles scaenas gentis truculentae.”

(Waquet 1942, p. 42)

“With mighty weight our men prepare great beams

Of wood, whose outmost point is pierced by tooth of steel,

To swiftly penetrate the Danish siege machine.

With doubled beams of equal length they fabricate

What in the vulgar tongue are known as “mangonels”

From these great stones are hurled and while they cast them down

They crush the humble platforms of the savage race.”

(Adams and Rigg 2004, p. 34)

Background

The first clear description of a traction trebuchet in Europe comes from Thessalonika in the late sixth century, in the Miracula of St. Demitrius from the early seventh century (Lemerle 1979). A raiding army of Avars lay siege to the city of Thessalonika and built on site machines which is translated by Vryonis Jr. (1981, p. 384) to:

“...were tetragonal and rested on broader bases, tapering to narrower extremities. Attached to them were thick cylinders well clad in iron at the ends and there were nailed to them timbers like beams from a large house. These timbers had the slings hung from the back side and from the front strong ropes, by which, pulling down and releasing the sling, they propel the stones up high and with a loud noise. And on being fired they sent up many great stones, so that neither earth nor human constructions could bear the impacts.”

After this, the machine seems to become widespread in the eastern Mediterranean; though its use and routes are far too varied to mention here (Petersen, 2013; Chevedden, 1998). In western Europe, the first probable description comes in Abbo of Saint-Germain-des-Prés poem Bella Parisiacae Urbis, which describes the siege of Paris from 885-886 (Abbo, n.d.; Waquet 1942; Skyum-Nielsen, 1967; Adams and Rigg, 2004; Dass, 2007). To repel the Vikings attacking the Grand Pont tower protecting the northern bridge over the Seine, the Franks build mangana in the towers.

The exact nature of these machines have been debated, and it is not entirely clear how much of these descriptions actually refer to the mangana. The translation above is a poetic one, not intended for exact detail. Yet the doubled beams that likely rose above the tops of the tower rampart and into Abbo’s line of sight from the city of Paris seems more likely to correspond to the long vertical aspect of a traction trebuchet’s frame, rather than the more compact Roman artillery. It is with the crusades, when siege warfare reaches the form recognizable to modern audiences, that both military manuals concerning the build of the machines and depictions start to appear. Much used here are the mid-13th century Maciejowski Bible images of a trebuchet in use, fol. 23v and 43v, and the late twelfth century manual by Al-Tarsusi (Cahen 1947, plate 2) containing building instructions and schematics.

Truly massive versions of these machines are reported, taking crews of hundreds of men. However, machines such as the ones placed on the watchtower of Paris would, by necessity, have been significantly smaller. The location, available personnel and projectiles all make a large machine unlikely, and it does not appear from the descriptions of the event that either side made use of the destructive force such a large machine had. Following the construction of the mangana, Abbo reports on bashing of heads and shields, something that resonates better with smaller projectiles than with the massive blocks of hundreds of kilos the larger machines could throw (Waquet 1942). It also seems unlikely that a tower, possibly unfinished, would have access to large projectiles within its walls. The destruction of the shelters of the Danes could indicate larger damage, but as these are likely the hide covered tents set up a few lines earlier, it seems unlikely that much force would be needed to cause permanent damage to them. For this reason – and because 7-8 people are easier to gather consistently than 15-20 – we have stayed with the smaller machines, which throw rocks in the 2-5 kg range.

The evidence in the source material implies that these machines were built rapidly. The Avars at Thessalonika rolled up, spent the night and the following day building a variety of siege engines, which were ready for use by day three (Vryonis Jr, 1981). The Franks in Paris built the mangana during the first day of the attack, possibly having prepared the materials beforehand (Waquet, 1942). The material requirements for the trebuchet were not difficult to fulfill. The throwing arm of the Avar’s machines are described in the extract above compared to the “beams of a large house” and could quite literally have been a beam from a house. The trebuchet in folio 23v of the Maciejowski bible (mid-13th century) shows an arm that has not even been stripped of its bark. Petersen (2013) argues that their complexity is what permitted a carpenter to build a faulty machine at the unidentified Sylws in 664. As this machine only fired 3 times before its destruction in a counter attack, it seems more likely to have been a minor fault, possibly intentional, with the release hook than a structural issue.

Construction of a traction trebuchet

The first functional traction trebuchet that our group built was in 2008, by a team consisting of a Computer Science professor, students studying game development, and a lumberjack. The main structure was trees that were cut down on-site on the Saturday morning of the construction weekend. The construction was on the grounds of the University College, which allowed us to select the trees to cut down. The remaining materials, including nails, rope, and a leather hide had been purchased before construction began. For the following builds we have been several times at the Medieval Festival held at Hamar each June, and in 2017 the Middelaldercenteret in Nykøbing Falster were kind enough to allow us to come and use their reconstructed hand tools to build a version entirely with period tools, materials, and construction. The wood for the builds has come from trees chopped down either on site or nearby, with the owner’s approval. We have used a variety of trees, such as pine, birch and hazel. Other than the removal of branches and twigs, we have kept the logs in their original format, neither making planks nor shaving off more of the bark than necessary.

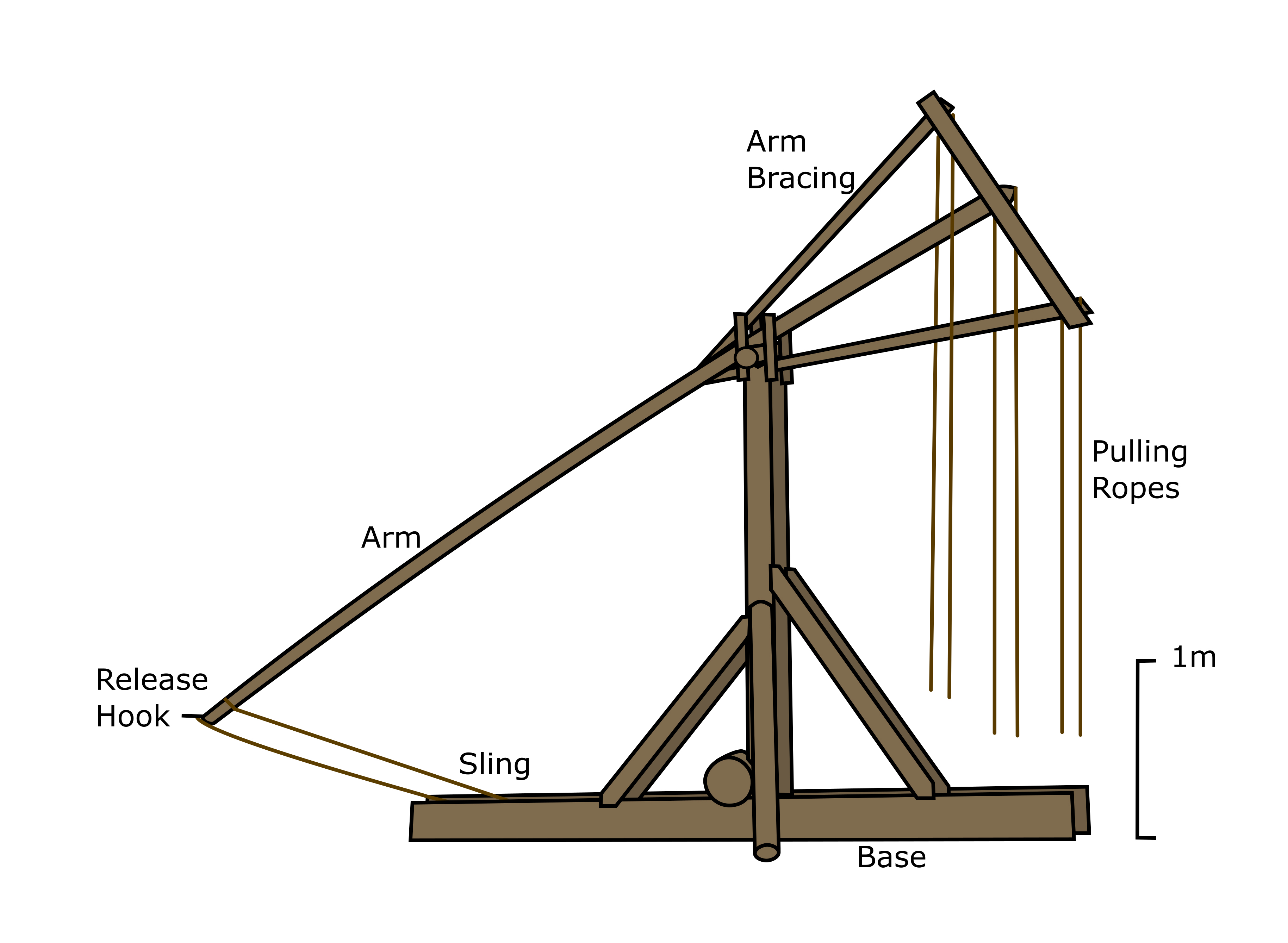

An illustration identifying the following elements of our trebuchets can be found in Figure 5.

Fig 5. Labelled diagram of a traction trebuchet.

The Base

The machine was of the simplest form, with two long runners each with an upright standing in the middle of each of the runners. The uprights were then supported by triangular bracing from both ends of the runners, and a cross brace that lies at 90° to the runners. This bracing is designed support an axle that will sit on top of the uprights. The strongest bracing is placed on the back side of the upright as the pulling force will be slightly offset toward the back of the machine where the crew is standing. The uprights on the machines we have built range from a small machine with 1.8 m uprights to a large machine with 3.5m uprights with between 10 and 25cm diameter.

The Axle

For the axle we selected a short piece of wood which looked straight. This was rounded smooth by placing nails in the center of the log at each end and spinning the log while it rested on the nails. We have also used axles with almost no rounding, and they also work perfectly well. As the axle does not rotate quickly it only needs to be somewhat rounded. The axle has a slight notch, a flattened area cut into it for the arm to rest against. The axle is 150 cm long and about 10 cm in diameter. This makes it wide enough to span the uprights, allowing a person to walk between the uprights.

The Arm

This is the most critical piece of wood in the whole machine. It is put under the largest strain and is the most likely to break. We have broken 4 arms across the 13 machines we have built. The arm is more likely to break if it is dry timber. Putting an axle through the center of the arm beam would significantly weaken the arm. Most modern reconstructions use a metal bar so that the axle is strong but thin and does the least damage to the arm. Our solution, which appears to be consistent with some historical depictions, is to place the arm on top of the axle (Chevedden, et al., 2000, p.467). This placement of the arm means that under load, when the arm is pulled by ropes attached to one end and pulling against the stone on the other, the arm has full strength as it pushes down on the axle which then transfers the force to the uprights. The arm should be made of green wood. This allows the arm to bend and provides both protection from breaking, and a smoother release as the force applied by the crew pulling the arm is absorbed by the bend of the arm.

The Arm Bracing

Perhaps the most controversial discussion about traction trebuchets is the orientation of the bracing on the throwing arm. There are two alternatives, vertical bracing like an axe, or horizontal bracing like a rake. The majority of reconstructions use the rake style bracing where the rope end of the arm becomes wider. It provides a wider area for the crew to stand while pulling on the ropes. The Maciejowski Bible (mid-13th century) depictions folios 23v and 43v where the axle is cutting through the arm itself, seem to be showing vertical bracing. The argument for the axe bracing is that the stress for the arm is in the vertical direction, and so the bracing should be aligned to support the arm in that direction. The vertical bracing also offers a means to support the axle by wedging it between the arm and the brace on the lower side of the arm. By wedging the axle in place both the axle and the arm retain their full mechanical strength, and the arm is supported when there is load. The axe bracing also allows the axle to be much shorter. This makes the machine narrower and decreases the stress on the rest of the machine. This also decreases the twisting force created if there are ropes attached to the spread-out end of a rake brace.

The Pulling Ropes

There are six ropes attached to the braced end of the arm. This allows for a normal crew of six people pulling, which can easily be increased to twelve with two people per rope. By attaching the ropes to each end of the bracing and to the center where the arm ends, as in the Maciejowski Bible (mid-13th century) fol. 23v, the spacing of the ropes provide spacing for the pulling crew. Given the axe bracing all the pullers are pulling in line with the rotation of the arm, thus there is no twisting force created by having some crew members pulling slightly earlier than the rest.

The Sling

The sling we constructed was a simple thick leather sling which merely folded over the rock to throw. There was no pouch or cup. The sling was attached on one end by a rope to the long end of the throwing arm, where it was securely tied. The other end of the sling had a rope with a loop, to fit on the release hook on the far end of the throwing arm. This is similar to the pole/staff sling. The length of the sling rope affects the point of release. The longer the rope the later the release point.

The Release Hook

At the tip of the long end of the throwing arm we attached a metal spike. The spike needed to be strong enough to hold the force of the rock in the sling. For aiming and adjustment purposes we made sure the spike could be bent by hitting it with a hammer. This allowed us to adjust the point of release. Bending the spike up can also be used to delay the release. It is easier to adjust this spike than shorten the sling length.

Performance

We have made 13 of these traction trebuchets over 9 years. While the core of the crew has returned from year to year and have become quite experienced in terms of firing the machine, the carpentry skills of most of the contributors are limited to non-existent. Therefore, our build times should be considered a maximum rather than the output of a similar sized team with wood-working experience. It is worth mentioning here that anyone capable of handling an axe and doing fairly minor precision work on a log, will manage just fine. On the occasions when we have built them with just hand tools, we have used axes, saws, chisels and spoon drills.

The time needed to build these machines has for us ranged from a minimum of 12 hours with power tools and a larger portion of more skilled crew members, to 30 hours with hand tools and a less skilled crew. For the Hamar Medieval Festival, an event we have participated in several times, we have usually started the build on the Friday afternoon and completed it on the Saturday morning for the first demonstration at around midday Saturday. When the Middelaldercenter at Nykøbing Falster let us come there to borrow their hand tools over a weekend in the summer of 2017, we had hopes of improving our build times. Unfortunately, hot weather and inexperience with the tools meant that we did not manage a quicker completion, but we were still able to build the machine in 2 days. We were also able to illustrate how easy the machine is to move. After construction the machine was moved for health and safety reasons. The arm was taken off and eight people moved the frame and one person moved the arm. This is the crew necessary to operate the machine plus two extra set of hands. Admittedly the frame only had be moved about 20 m, but it was not a particularly taxing enterprise. Thus, the trebuchet could be built out of the range of the fortifications artillery either just before or at the beginning of the siege, then quickly moved into position where it was needed.

The largest machine to date was 3.5 m at the axle with a 6.5 m throwing arm, and the smallest was 1.8 m at the axle with a 3 m arm. The majority of machines have been in the 2 m-2.5 m range at the axle. Our crew generally consisted of six pullers and one sling holder. The pulling crew has usually had the two strongest (and often tallest) people in the middle position. They have also been responsible for using their rope to slow the arm down once it reaches the end of its curve. Instructions have been simple, merely to keep the rope taut and then pull straight down when the sling holder calls for it. The position of sling holder requires focus and slightly more training than the pullers, but it only takes a few throws to learn it. Pulling teams consisting of two adults and four children can easily throw as far as a team of four adults. Our projectiles have been whatever rocks we can find in the surrounding area. We try to keep them at an even size and weight, but there are naturally variations. Despite this, these machines consistently throw rocks in the 2-4kg size about 80 m, with a maximum of 120 m with a light rock and coordinated team.

The performance of these machines is remarkably consistent. The aim is corrected by adjusting the release hook. After a few throws the adjustments are mostly finished, and the length of throws are within about a 5 m spread, and 10 m length variation. The curvature of the throw has a high arch, which means that the rocks are coming down at a steep angle, which would not be effective in damaging a wall, nor are they of a size where that would cause significant damage. They are coming down with a lot of force, as witnessed by the 2-4 cm indents the rocks tend to leave on firm ground. Flat and slightly angled roofs, shields and humans are all reasonable targets for this kind of weapon.

When we timed the rate of fire in Denmark, we managed 4 projectiles in just over a minute, averaging to roughly 20 seconds per projectile, as long as these were laid out within easy reach of the sling holder. Comparing this to the counterweights that Middelaldercenteret demonstrates the use of every day, the difference becomes quite obvious. While our machines are too small to do any large-scale damage, like the counterweight could, the rate of fire means that the traction machine could fire off roughly thirty projectiles in the ten minutes Peter Vemming Hansen (1989) calculated that it would take to load and fire Middelaldercenteret’s small counterweight. The larger counterweight has a record load time of 4 minutes 20 seconds but this is not a speed that can be maintained over a longer period (Petersen, 2018). A traction trebuchet of this size is therefore a different type of weapon to the counterweight trebuchet, with a rapid construction used for rapid firing against humans and lightweight constructions.

Breakages

While testing and demonstrating these machines we experienced several failures. The most common is the throwing arm breaking just in front of the bracing. This generally occurred when using an arm that has sat outside for a year, or that was dry before it was added to the machine. The advantage of using green wood in construction is that even when the wood breaks it does not fail completely. It bends and cracks but many of the fibers remain attached. Thus, the machine does not collapse but rather slumps or bends. All joints are held with rope, and on most builds nails were also used. If a nail fails, the rope on the joint holds the machine together. A replacement arm can be rapidly constructed and put in place. When building the machines, we usually ensured that there was a second length suitable for a throwing arm, in-case of breakage. The machines have been remarkably robust, and we have never hurt a crew member with any part of the machine.

Conclusion

These machines require no complex engineering skills or tools. Anyone with some building experience and knowledge of how to use an axe can recreate one. The estimates that Abbo and the Miracula give for build times are well within what our experiments have shown to be feasible. While our machines have been built for public entertainment, and as such have not been placed under the more rigorous testing such as what Tarver did with his, the consistency of throwing lengths despite variations in machine, personnel and projectiles clearly indicates that these are both simple and reliable weapons. Even on the occasions when the machine breaks, it is usually a relatively undramatic break in the arm and does very little damage to the frame itself. This brings up a range of interesting questions. When the machine is coming into use, how does transmission happen? Theoretically this machine is simple enough that an enterprising carpenter could see one in use, and then build it. What kind of damage does a stone thrown by a traction trebuchet do to a shield, or a helmet, or other military equipment from a given period? Abbo suggests a variety of shattering and crushing. How easy is it to aim at personnel or equipment on a rampart and from a rampart to a standing army on the ground? Siege engines being shattered by other siege engines is not a rare occurrence. What happens with the mechanics when the machines, crews and projectiles get bigger? There are records of crews in the hundreds and even a live ass being used as projectile. (Chevedden, et al., 2000) There is clearly the potential for a lot of work to be done on the use of traction trebuchets in practice!

Advice

These machines are weapons. There are large moving parts and potential risks to the crew and bystanders. When throwing rocks you are using the weapon in full military mode as it was originally used in a theatre of war. Thus, safety is critical, especially when showing these machines in public places. You need to clear an area of about 50m behind and 120m in front. The furthest to the side of the machine that a stone has landed in our testing is 10m. Thus, any audience members can be lined up parallel to the machine standing 15m away. You should always instruct the audience to look up into the sky if there is a misfire and walk slowly away from the stone. Any vertical misfire will have multiple seconds hang time, giving people plenty of time to see the stone and walk slowly out of the way.

In our experience machines that were smaller than 2m at the axle became extremely inaccurate. Our attempt merely led to a multitude of misfires in both directions. Even with a crew of just two people we were not able to make the machine respond in a consistent manner.

Keywords

Country

- Denmark

Bibliography

Abbo, Bella Parisiacae Urbis [Manuscript-online] Available at: Gallica.bnf.fr: https://gallica.bnf.fr/ark:/12148/btv1b9067841t.image [accessed 08.08.2018] Paris, Bibliotèque Nationale de France, MS. Lat. 13833.

Adams, A. and Rigg, A.G., 2004. A Verse Translation of Abbo of St. Germain’s Bella Parisiacae urbis. The Journal of Medieval Latin, 14. pp.1-68.

Cahen, C., 1947. Un traité d'armurerie composé pour Saladin. Bulletin D'études Orientales, 12, pp.103–163.

Chevedden, P., 1998. The Hybrid Trebuchet: The Halfway Step to the Counterweight Trebuchet. In: D.J. Kagay and T.M. Vann, eds., 1998. On the Social Origins of Medieval Institutions: Essays in Honor of Joseph F. O’Callaghan, Leiden; Boston: Brill, pp.179-222

Chevedden, P., Shiller, Z., Gilbert, S.R. and Kagay, D.J., 2000. The Traction Trebuchet: A Triumph of Four Civilizations. Viator, 31. pp.433-486.

Dass, N., 2007. Viking Attacks on Paris: The Bella parisiacae Urbis of Abbo of Saint-Germain-des-Prés, Paris; Leuven; Dudley: Peeters.

Hansen, P.V., 1989. Bliden - Et rekonstruktionsforsøg, Nykøbing: Museet Falsters Minder.

Lemerle, P., 1979. Les Plus Anciens Recueils des Miracles de Saint Démétrius et la Pénétration des Slaves dans les Balkans, Paris; Centre Nationale de la Recherche Scientifique. 2 vols.

Maciejowski Bible (mid-13th century), [Manuscript-online] Available at: Morgan Library and Museum website: http://ica.themorgan.org/manuscript/thumbs/158530 [Accessed 22 May 2018] New York, Pierpont Morgan Library, MS M.638.

Petersen, L.I.R., 2013. Siege Warfare and Military Organization in the Successor States (400-800 AD). Leiden; Boston: Brill.

Petersen, T., 2018. Discussion of Counterweight firing times with the curator of Middelaldercenteret in Nykøbing Falster. [facebook conversation] (Personal communication, 15 April 2018).

Skyum-Nielsen, N., 1967. Vikingerne i Paris: Beretninger fra 9. Århundrede, Munksgaard; København: Selskabet til historiske kildeskrifters oversættelse.

Tarver, W.T.S., 1995. The Traction Trebuchet: A Reconstruction of an Early Medieval Siege Engine. Technology and Culture, 36(1), pp.136-167.

Vryonis Jr., S., 1981. The Evolution of Slavic Society and the Slavic Invasions in Greece. The first major Slavic Attack on Thessaloniki, A.D. 597. Hesperia: The Journal of the American School of Classical Studies at Athens, 50(4), pp.378-390.

Waquet, H., 1942. Abbon. Le siege de Paris par les Normands. Reprint 1964. Paris: Société d’Edition “Les Belles Lettres”.