The content is published under Creative Commons Attribution 4.0 International license.

Reviewed Article:

An Experimental Comparison of Impressions Made from Replicated Neolithic Linen and Bronze Age Woolen Textiles on Pottery

Textile impressions on pottery provide evidence for fabrics and weaves in areas where the fabrics themselves do not survive. This article argues that the impressions can provide information on the uses of different fibres, the weaving technologies and possible trading or agricultural advances connected with these fibres. This experimental study attempts to develop a method of identifying whether the fibres used in pottery impressions of Northern European prehistoric textiles are wool or made from plant bast fibres, specifically flax in this comparison. It was believed at first that it may be possible to identify the fibres in these impressions, since woollen yarn would leave a rougher, fuzzier impression when compared to the smoothness of flax yarn. The results of this experiment indicate that it was easier to identify woollen and flax fabrics from the impressions left from the different spinning methods used in the Neolithic and Bronze Age.

Introduction

This article aims to show that it may be possible to identify woollen fabrics and flax fabrics from the impressions left in ceramics. To do so, the author has replicated the textiles most commonly used in the Neolithic and Bronze Age period (flax and wool) with the help of a large and experienced group of volunteers from the Devon Guild of Spinners, Weavers and Dyers; these fabrics were then impressed into two types of clay (fine earthenware and natural Devonshire clay) to recreate impressions that could be analysed. The volunteers spun the yarn for the woollen fabrics and this ensured that mistakes or flukes could be avoided by using a wider range of experience to produce a greater variety of wool. This work has been guided by a brief study of original textiles found in the Swiss Lakes, now at the British Museum and viewed with their kind permission.

Should clear differences between wool and flax impressions be identified, this will allow other researchers to refine this experiment and possibly identify earlier woollen or plant fibre textiles that have not survived, through their ceramic impressions alone. There has been no work to replicate and compare woven woollen and plant fibre impressions such as linen. Should major differences be found, this would enable archaeologists to identify wool and plant fibre impressions with greater reliability across a wider area, further helping to reduce the gap in our knowledge of prehistoric textile technologies.

Previous work

Textiles

Textiles are notoriously difficult to find outside of anaerobic conditions, especially in temperate conditions such as Northern Europe (Gillis and Nosch, 2007). As such, there are wide geographical gaps in our knowledge of herd structure and textile crafts. Wool survives better than plant fibres (Hurcombe 2000, 156; Barber 1991, 19-20), but both need the correct anaerobic conditions to survive (Gillis and Nosch, 2007), such as in peat bogs or marshes. Some of the best Neolithic finds (including textiles containing two-ply linen yarn and flax working tools) come from the Swiss lakes (Barber 1996, 85-91). Some full early Bronze Age costumes were discovered in Denmark in oak coffins placed in bogs, such as the Egtved girl’s skirt and blouse (Randsborg 2011, 13; Bender Jørgensen 1986). Most of these costumes were constructed from simple woollen garments of single-spun yarn in plain weave.

No linen was used but there were unusually rich bronze grave goods accompanying these costumes. As linen would have survived with the wool, and given the richness of these graves and the effort taken to carve the coffins, we can theorise that wool was a prestigious item at this time in Denmark. We are unable to reach that conclusion elsewhere until more evidence (preferably similar graves) is discovered. However, in many areas only secondary evidence of textiles remains, such as loom weights, spindle whorls, or impressions of textiles in metals or ceramics (Lomborg 1975; Barber 1991; Broholm & Hald 1948, 295; Bender Jørgensen 1992, 114; Rindel 1993, 20; Davidsen 1982; Sarauw 2006, 39).

Experimentation and ethnographic research are invaluable tools for enhancing and reviewing archaeological theories, particularly in the field of perishable material culture (Jolie & McBrinn 2010, 159). Archaeologists analysing textiles tend to focus on easily identified aspects: thread count, fineness of fibre, direction of spin and so on (Giszuk 2007, p 13; King 1978). These can be identified using scientific tools including UV-visible spectrophotometry; high performance liquid chromatography (HPLC); optical light microscopy; polarized light; Scanning Electron Microscopes; X-ray pictures and digital cameras. These techniques are often expensive and require specialists or experience to use properly, yet provide excellent pictures and information to interpret the fabrics and some aspects of the society in which they were created (Knudsen 2007, p. 103 – 111). Although providing vital information about the textiles, these techniques often do not reveal information needed in practically constructing such fabrics. Such analysis often focuses on information not of primary importance to weavers and spinners; on thread count first, then weaving patterns, followed by direction of spin. Direction of spin makes little difference to the weaving of a fabric; it is more of a traditional cultural practice that depends on the community of practice surrounding the spinner (Hammarlund 1998; Giszuk 2007, p. 14).

As a result, crafts people have often failed to reconstruct ancient textiles through archaeologist’s reports alone (Hammarlund 1998). Once these problems were identified by weavers like Hammarlund, fabrics were grouped by appearance first, then sub-grouped by tightness of spin and type of fibre used, and then further by weaving patterns (Hammarlund 1998). The importance of consulting craftspeople is clear to archaeologists who have worked with craftspeople in analysing the textiles. They have drawn more accurate conclusions and produced more accurate reproductions, because the experience of craft practitioners has led them to focus on slightly different details (Barska 2007, p. 53; Andersson, 2004, p. 196).

Textile impressions

Impressions are not the common area of focus in the field of prehistoric textile research, which is generally more concerned with methods and tools of production (King 1978; Barber 1991); materials and their uses (Hurcombe 2004; 2008; Barber 1991); ethnographic evidence to better explain the chainé operatoîre (Giszuk 2007; Andersson 2007; Hammarlund 1998); and reconstruction of ancient textiles and dress (Randsborg 2011; Bender Jørgensen 1986). However, a great deal of information may be gained from impressions, especially as these may be the only surviving traces of textiles in an area where the fibres and the wooden tools have decomposed.

Metal impressions are formed as positive impressions, which are made when rust forms around metal when it comes into contact with (and presses around) a textile. (Makkay 2001, 8-9). These can be very delicate and may not be identified as textile impressions; in the past, such impressions have been destroyed by museum workers cleaning the metal (Doumani & Frachetti 2012; Makkay 2001).

Ceramic impressions are able to survive the cleaning process and usually occur on the more solid bases of pots, improving the chance of survival (Hurcombe 2000, 163). They are also able to capture more detail of the long-decayed fabric than metal impressions (Hurcombe 2000, 163). Despite this, studies of ceramic impressions have focused solely on identifying the textile’s weave structure; most authors have claimed that it is impossible to discern plant yarns (such as flax) from woollen yarns simply from the impressions alone (Doumani & Frachetti 2012, 377). Any work to replicate and analyse these impressions has been poorly managed (Holmes 1901; Drooker 2001a) or focused solely on yarn (Hurcombe 2008) or cordage impressions (Hurley 1979), not woven fabric.

Plant fibres

Which materials were used in prehistoric textiles and when they were introducedare also debated. A variety of plants were used in creating the earliest textiles (Hurcombe 2008; 2009), with flax and nettle being the most widely used (or the best surviving types) (Barber 1991, 19).

Wool

It is believed that wool was introduced to Northern European spinners and weavers after the arrival of agriculture from the Eastern Mediterranean in the Late Neolithic (c. 3000 BC), when it became one of the most widely used fibres (DeRoche 2012, 445; Ryder 1964). However, the quality, roughness, amount of kemp in the fleece, and the usefulness of sheep wool at this point are still debated (Hurcombe 2000, 2008; Christainsen 2004; Ryder 2005). Primitive sheep breeds had coats containing more hair and kemp than wool, which are difficult to spin and extremely rough; these features can still be found in the Soay, Faroe, Manx, and Boreray breeds. It would take time to breed out excess kemp to create a softer, more woollen fibre that was easier to spin and more comfortable to wear. There is no direct skeletal evidence from the sheep themselves suggesting when this change in the fleece occurred. The age of the sheep bones is currently the best evidence of the change in herd structure from meat production to fleece use, but even these do not survive well (Ryder 1964).

Methodology

In order to ensure that the yarns and fabrics created were as close to known Neolithic and Bronze Age fabrics as possible, the author arranged a visit to the Blythe House collections of the British Museum’s prehistoric Swiss Lake fabrics. Although the region of their discovery is known, exact findspots are not since they were collected by antiquarians in the Victorian era. However, their general location and style suggests the fabrics were from the late Neolithic or early Bronze Age. The direct and detailed examination of the fabrics’ scale and structure, the tightness of spin, and the varying treatments of the fibres used in genuine Neolithic and Bronze Age fabrics allowed for a more precise replication for these experiments.

Interestingly, all the woollen fabrics were woven using single spun threads rather than the plied yarns used in the linen fabrics, despite being found in the same areas. Furthermore, there was a great variety in how the fabrics were woven: some were fine and loose, others where tightly-woven. Whether this was a deliberate choice of the weavers, or some had tightened up over time is not certain. Because of these observations, it was decided that the Soay wool would be left as a single strand, while the flax fibres would be spun and plied into a two-strand yarn, and that there would be a variety of loose and tightly-woven fabric samples.

The fabrics used for this experiment were hand-spun by the author, a professional flax spinner, and a group of volunteers from the Devon Guild of Weavers, Spinners, and Dyers and hand-woven by the author on a tapestry loom. The Guild volunteers spun single threads of Soay sheep wool, while the author and the professional spinner spun thin and thick two-ply flax threads. The samples were woven at different tensions and with various numbers of threads which created fabrics of various tightness and densities. In this way it was possible to see what type of fabric left the best impressions in the clays.

Four flax samples were woven and numbered. F1 and F2 were woven from the professional's spun flax, which was softer and smoother than F3 and F4, which were spun by the author. F3 and F4 were remarkably coarse and wire-like compared to F1 and F2. This difference was partially to indicate the differences between flax spun by experienced spinners and by novice flax spinners. The woollen fabrics samples were numbered W1 to W8 and were woven in a variety of ways. W1 was the only two-plied woollen sample, to give an indication of the differences between plied wool, single thread wool, and plied flax. W2 and W3 were woven with double the amount of weft threads compared to warp threads, as were W6 and W7 although these were the most loosely woven; W4 and W5 were woven with an equal number of warp and weft threads (so making a balanced fabric); W8 had more warp threads than weft. See Table 1 for more details.

| Sample no. | Wool | Flax | Warp per cm | Weft per cm | Z-spin | S-spin | Thread thickness | Plied yarn |

| W1 | Y | N | 3,6 | 3,6 | N/A | Both | 2-3 mm | Y |

| W2 | Y | N | 4,4 | 8,8 | Weft | Warp | 1 mm | N |

| W3 | Y | N | 4,8 | 10 | Warp | Weft | 1 mm | N |

| W4 | Y | N | 7,6 | 7,6 | Both | N/A | 0.5-1 mm | N |

| W5 | Y | N | 4,4 | 5 | Both | N/A | 0.5-1 mm | N |

| W6 | Y | N | 3,6 | 6,8 | Weft | Warp | 0.5-1 mm | N |

| W7 | Y | N | 4 | 7,2 | Warp | Weft | 0.5-1 mm | N |

| W8 | Y | N | 7,6 | 5,6 | N/A | Both | 1 mm | N |

| F1 | N | Y | 17,2 | 10,4 | N/A | Both | 0.45 mm | Y |

| F2 | N | Y | 14,4 | 4,8 | N/A | Both | 0.7 mm | Y |

| F3 | N | Y | 3,6 | 9,6 | Weft | Warp | 1-1.5 mm | Y |

| F4 | N | Y | 4,4 | 6,8 | N/A | Both | 1-2 mm | Y |

Table 1. Details of the various fabrics reconstructed for these experiments.

Clay tablets were made in ten centimetre squares, eight millimetres deep, from fine white Earthenware and rougher natural Devon clay from the Exmouth area. The finer clay would capture greater details of the cloth and highlight features that could show the differences between the impressions, while the rougher clay would provide an example of the quality of impressions in rougher ceramics more common in Neolithic times. The fabrics were pressed into the clay by a weight of 1 kg over a small area for five minutes. After the fabric had been removed, the clay tablets were then marked according to which sample had been used to create the impressions (F1-4 and W1-8 accordingly). The tablets were air dried at ambient temperatures for ten days, then biscuit fired in a kiln over approximately ten hours starting at a low heat and gradually increasing to 10000C.

Results

The fine clay impressions allowed us to compare clear impressions against the coarser clay impressions and be able to identify common features that may have been overlooked in the rougher impressions. It certainly became more difficult to discern features such as plying, though the weave structure remained clear in all the coarser clay impressions. As the clay tablets were all made in the same way, the distinctness of the impressions largely relied on how tightly the fabrics were woven. Those that were woven tightly produced lighter impressions, whereas those that had fewer threads (and thus were loosely woven) produced the clearest impressions, possibly because there was less resistance against the clay when they were pressed against it.

Flax fabric impressions

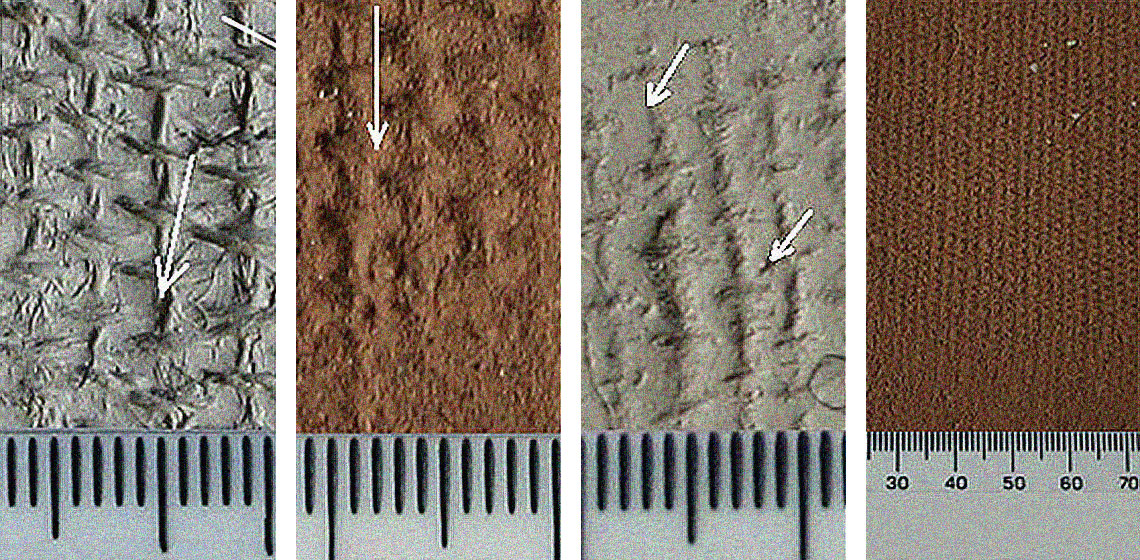

The fine clay gave the best impressions of the whole test, especially with the rougher and thicker yarn spun by the author. The fine and tightly woven fabric samples of F1 and F2 left shallow and poor impressions, while F3 and F4 shows in detail a number of characteristics that can be seen in the coarser clay impressions. The double-twist of the plied yarn is clearly visible in F3 (See Figure 1, highlighted on both warp and weft yarns in white). The weft yarns also slant slightly in these rougher fabrics, angling down on their left and up on their right sides, although it is more obscured by the details of the plied imprints from the yarn.

The coarser clay impressions display clear weave structure from all samples, which allowed the thread counts to be reliably ascertained. An example of plied fabric was identified in one section of F4, where there is an apparent lack of twist in the fabric (See Figure 2, highlighted in white). Here two single threads appear to sit alongside each other before running beneath a weft thread; this is a common illusion in plied yarns that can easily identify them. F2 exhibited a different impression of the twist of a plied yarn, where two threads wrap around each other (See Figure 3, highlighted in white). The slant on the weft yarns is still visible in the coarse clays of F3, F4, and even in the finer fabric impression of F2 (less so than in the white earthenware impressions). It is likely that the low quality of the yarns has prevented as many details from being imprinted.

Woollen fabric impressions

Great detail was captured in the fine clay impressions, expect for those tightly woven; loosely woven fabrics resulted in the best impressions. The threads were well-spun enough to ensure that there are no loose hairs to obscure the details on this piece and this clarity showed details of the twist on the warp and weft on several impressions, including W2, W3, W5, W7, and W6 (See Figure 4, highlighted in white). Through this, the width of the wool, thread count, weaving pattern, and S or Z-spin direction could be identified and recorded. Despite this, there is no evidence of slanting on the weft thread impressions as there is in the flax impressions.

The tabby weave structure remained visible in the coarser clay impressions, allowing for an accurate thread count and estimation of the fineness of the yarn and overall fabric. There is less twist visible on these threads, even in comparison to the flax fabric impressions in the same coarse clay; the thread twist is visible only on W2 (See Figure 5, highlighted in white). There is no slanting to the weft visible; as with the fine clay impressions, the weft follows the direction it was woven in. However, there is less detail and clarity in the woollen fabric impressions compared to the flax, despite it being the same clay. This does not appear to be due to the hairiness of the wool, there are no hair-like scratches on the clay surface.

Discussion

Several features can be identified from this experiment that can distinguish between woollen and flax fabrics.

Firstly, plied yarns can be distinguished from single threads from these impressions, as the extra twist on these yarns create a slanted impression that is distinct from the single threads’ impression, which lies straight, as shown in figure 6.

This slant is formed when only the part of the weft thread that passes in front of the warp is imprinted onto the clay. The twist on the plied yarn means only one side of the weft thread is pressed into the clay, and this leaves a gap where the rest of the weft continues to twist up and run behind the next warp thread. Should a plied fabric be pressed firmly into wet clay, this gap may not appear; however, these conditions should leave suitably deep impressions to observe the full plied nature of the fabric. In comparison, single-spun threads do not leave this impression, since they have less width to move behind the warp threads and lack the twist found in plied yarns. Instead, they produce a single impression that simply follows the line of the weaving. As only flax was plied in pre-Iron Age periods, this could indicate which impressions were made from flax or woollen fabrics (Rast-Eicher, 2012, 380 and 384).

Secondly, the twist in plied and single-spun threads creates different impressions; single-spun threads have a smaller, tighter twist that is too closely spun to be a plied yarn. In comparison, the twists of plied yarns are either thicker than the single-spun twist or appear to be two threads sitting alongside one another (See Figure 7).

This could only be clearly seen in the fine clay during this experiment and therefore may not be visible in the archaeological record, but it allows another indicator for woollen yarns compared to flax yarns.

Lastly, the overall impressions formed by the finely spun and tightly woven linen fabrics on the natural Devon clay were smoother and more visible than those produced by woollen fabrics woven in the same way. Though details of the spinning were lost, the thread count and the weaving style can be established. Clearly, the smoothness of the linen fibres allowed the fabric’s structure to be well-imprinted on the clay. Should further details have been added (such as embroidery on the fabric’s surface), this author believes they would be imprinted with equal clarity. In comparison, the woollen impressions are either barely visible or do not have as much detail and precision as the linen, see figure 8 for a comparison of the impressions. The tightness of the woollen fabrics appears to have prevented the fabric from being pushed into the clay in the same manner as the linen fabrics, resulting in an impression of lower quality. Although this is a minor difference, it would allow for identification of potential plant fibre fabrics or woollen fabrics, as long as the ceramic impressions are not damaged.

Identifying fabrics with plied yarn instead of single threads is important, as Bronze Age spinners (over Northern Europe, specifically in areas such as Germany, Switzerland, and Scandinavia) chose not to ply their wool, while Neolithic spinners plied flax (Grӧmer, 2012, 31 and 55; Franzén, Lundwall, Sundstrӧm, and Andersson Strand, 2012, 353-357). This could be because the thickness of woven fabrics was more important to the spinners than anything else, since both the linen and woollen fabrics (from the Neolithic and the Bronze Age respectively) have a similar thickness. This is supported by the fact that primitive wool fibres are so short it is hard to produce plied yarns that are thin enough to weave fabrics 3mm thick, since it is hard to draw out a few hairs at a time and maintain control of the spinning.

Although this work has produced interesting results, the comparison of sheep’s wool with flax only covers a small area of plant bast fibres used in prehistoric textile production. To confirm these findings, the experiment should be repeated with fabrics spun and woven from nettles and from the finer forms of tree bast (see Hurcombe 2008 for a comprehensive list of bast fibres). These materials were used to a great extent in prehistory and could produce different results from the findings here.

When replicating this experiment, it is advised to research the common clay types used during the Neolithic period and the Bronze Age in your area. This would produce more accurate results, as the impressions produced would be more similar to those found in the archaeological record. While the natural Devon Clay used here was invaluable for providing a close approximation to the prehistoric impressions, further research into clays similar to those types used for pottery in the Neolithic period and the Bronze Age would produce more accurate results.

It is also advised to conduct further research on comparing the hand-spun and hand-woven qualities of the wool from primitive sheep breeds known today (such as the Faroe Island sheep, the Soay, the Boreray and the Manx, to name only a few). By comparing the impressions from each breed, first with each other, then with textile impressions from prehistoric pottery, it might be possible to observe which breed produces impressions that are more comparable with those visible in the archaeological record.

Conclusion

This experiment produced several indicators that can be used in identifying the fibres of a fabric impression in clay. The impressions produced by plied flax yarns differ significantly from single spun woollen yarns, an important distinction as wool remained un-plied until the Roman period, when sheep with longer fleeces were bred and introduced to the rest of Northern Europe. Another important indicator is that the tightly woven linen produced clearer impressions than similarly woven woollen fabrics; this was possible because the linen fibres are long and smooth and they lack the hairs that make up wool which also obscure a lot of the detail in the impressions. This is a significant indicator of which fibres were used in long-lost fabrics, as plant fibres were a staple of Neolithic textiles and wool was used almost exclusively in the Bronze Age. Identifying the fibres from pottery impressions also allows for a reasonably precise date for when certain fibres were used in prehistory, as they can be dated from the ceramics in which they are impressed. Further tests could be performed to get more data from a wider range of animal or plant fibres and common prehistoric pottery clays.

Country

- United Kingdom

Bibliography

ANDERSSON, E. B., 2007, Textile Tools and Production during the Viking Age. In: C. Gillis and M.B. Nosch (eds.) Ancient Textiles: Production, Craft and Society. Oxford: Oxbow, p. 17-25.

ANDERSSON, E., 2004, Reconstruction of Archaeological Textiles, a Source Critical Approach. In J. Maik (ed.), NESAT VIII, Priceless Invention of Humanity: Textiles. Łódź. Acta Archaeologica Lodziensia Nr 50/1. p. 195-197.

ANDERSSON Strand, M. GLEBA, U. MANNERING, C. MUNKHOLT and M. RINGGAARD (eds.), 2009, North European Symposium for Archaeological Textiles X, Oxbow Books, p. 129 - 139.

BARBER, E.J.W., 1991, Prehistoric textiles, Princeton University Press.

BARBER, E.J.W., 1996, Woman’s Work: The First 20, 000 Years - Women, Cloth and Society in Early Times. W. W. Norton & Co.

BARSKA, K., 2007, Roman Period Warp-weighted Loom from Ożarów Mazowieki, Poland. In: C. Gillis and M.B. Nosch (eds.) Priceless Human Invention – Textiles, p. 45-54.

BENDER JØRGENSEN, L., 1986, Forhistoriske textiler i Skandinavien (Nordiske fortidsminder). Ser. B)

BENDER JØRGENSEN, L., 1992, North European Textiles until AD 1000. Aarhus University Press.

BROHOLM, H.C. & HALD, M., 1948, Bronze Age Fashion, Gyldendalske Boghandel Nordisk Forlag

CHRISTIANSEN, C. A., 2004, A reanalysis of fleece evolution studies. In: J. Maik (ed.) Priceless Invention of Humanity – Textiles: NESAT VIII, 8–10 May, 2002. Acta Archaeologica Lodziensia 50/1. Ło´ dz´ : Ło´ dzkie Towarzystwo Naukowe, Instytut Archeologii i Etnologii PAN, p. 11–17.

DEROCHE, D., 2012, England: Bronze and Iron Ages. In: M. Gleba and U. Mannering (eds.), Textiles and Textile Production in Europe: From Prehistory to AD 400, Oxford: Oxbow Books. p. 444-450

DAVIDSEN, K., 1982, Bronze Age houses at Jegstrup, near Skive, central Jutland, Journal of Danish Archaeology 1, pp. 65-75.

DOUMANI, P.N. & Frachetti, M.D., 2012, Bronze Age textile evidence in ceramic impressions, weaving and pottery technology among mobile pastoralists in central Eurasia, Antiquity Vol. 86, No. 332, pp. 368-382.

DROOKER, P.B., 2001a, Leaving No Stone Unturned: Making the Most of Secondary Evidence for Perishable Material Culture. In P. B. Drooker (ed.) Fleeting Identities: Perishable Material Culture, pp. 170–186. Center for Archaeological Investigations, Southern Illinois University, Carbondale.

GILLIS, C. and NOSCH, M.B. (eds.), 2007, Ancient Textiles: Production, Craft and Society. Oxford: Oxbow.

GISZUK, M., 2007, The Academic Craftsman – Discussion on Knowledge of Craft in Textile Research. In: C. Gillis and M.B. Nosch (eds.) Ancient Textiles: Production, Craft and Society. Oxford: Oxbow, p. 13-15.

HAMMARLUND, L., 1998, Textiliernas fjärde dimension. Hantverkarens kunskap och redskap. En studie av romerska tuskaftsvävar från Mons Claudianus. HSFR D-nr F517/95.

HOLMES, W.H., 1901, Prehistoric Textile Fabrics of the United States, Derived from Impressions on Pottery. In: John W. Powell (ed.) Third Annual Report of the Bureau of Ethnology 1881-1882, pp. 393-425. Smithsonian Institution, Washington, D.C.

HURCOMBE, L.M., 2000, Plants as raw materials for crafts. In: A.S. Fairburn (ed.) Plants in Neolithic Britain and Beyond, Oxbow books, pp. 155-174.

HURCOMBE, L. M., 2004, Experimental archaeology. In C. Renfrew and P. Bahn (eds.) Archaeology: The Key Concepts. London: Routledge. p. 110–15.

HURCOMBE, L.M., 2008, Organics from inorganics: using experimental archaeology as a research tool for studying perishable material, World Archaeology 40.1, p.83-115.

HURCOMBE, L.M., 2009, Nettle and Bast Fibre Textiles from Stone Tool Wear Traces? The Implications of Wear Traces on Archaeological Late Mesolithic and Neolithic Micro-Denticulate Tools. In: E.

HURLEY, W. M., 1979, Prehistoric Cordage. Washington, DC: Taraxacum.

JOLIE, E.A. and MCBRINN, M.E., 2010, Retrieving the perishable past. In: J.R Ferguson (ed.) Designing Experimental Research in Archaeology.

KING, M. E., 1978, Analytical Methods and Prehistoric Textiles, American Antiquity, Vol. 43, No. 1. Jan., pp. 89-96.

KNUDSEN, L. R., 2007, Translating Archaeological Textiles. In: C. Gillis and M.B. Nosch (eds.) Ancient Textiles: Production, Craft and Society. Oxford: Oxbow, p. 103-111.

LOMBORG, E., 1975, Klokkebaeger-og senere Beaker-indflydelse i Danmark (Einflüsse der Glockenbecher – und der späteren Beaker-Kulturen in Dänemark: Ein Beitrag zur Datierung der Einzelgrabkultur), Copenhagen, Aarbøger for nordisk Oldkundighed og Historie.

MAKKAY, J., 2001, Textile Impressions and Related Finds of the Early Neolithic Körös Culture in Hungary, Budapest: self-publication.

RANDSBORG, K., 2011, Bronze Age Textiles: Men, women and wealth. Bristol Classical Press.

RINDEL, P.O., 1993, Bønder fra stenalder til middelalder vel Nørre Holsted. Nye arkaeoloiske undersøgelser på den kommende motorvej mellen Vejen of Holsted. Mark og Mntre. Årbog for Kunstog Kulturhistorie. Ugived of Ribe Amts Museumsråd.

RYDER, M.L., 1964, The History of Sheep Breeds in Britain, The Agricultural History Review (Vol. 12, No. 1, 1964), British Agricultural Society.

RYDER, M. L., 2005, The human development of different fleece-types in sheep and its association with the development of textile crafts. In: F. Pritchard and J. P. Wild (eds.) Northern Archaeological Textiles, NESAT VII Textile Symposium in Edinburgh, 5–7 May 1999. Oxford: Oxbow, p. 122–8.

SARAUW, T., 2006, Late Neolithic Houses and Settlement Structures, Bejsebakken. Nordiske Fortidsminder. Series C:4, Copenhagen (Det Kongelige Nordiske Oldskriftselbskab).