The content is published under Creative Commons Attribution 4.0 International license.

Reviewed Article:

Standardized Reporting of Experimental Iron Smelting - A modest (?) Proposal

The development of effective bloomery iron smelting has progressed over the past decades from the first repeated experiments into documented, effective, methods. This progression has primarily been the work of often isolated individuals, many with great practical experience as artisans, but most often with little formal academic training. The overall result is a patchwork of recording methods and descriptions, with greatly differing degrees of detail. Experience contrasts experiment, with many different approaches, and often objectives, as the goals. The author, drawing on almost 20 years of experience with bloomery iron smelting, and a foot in both the artisan and academic worlds, suggests some standard measurements and record keeping methods, presented in the hope of making the sharing of information easier.

As this article is also intended for first time experimenters, and both artisan and academic experimenters, indulgence from well experienced iron makers is requested over many detailed explanations, and the level of detail presented. It is well understood that those experimenters working within an ongoing series may not record all the suggested details every time.

Background: The State of an Art?

Over the last three decades, bloomery iron smelting has moved from the largely theoretical to the practical. Although there were certainly earlier attempts via experimental process to build workable furnaces, most of these attempts were basically unsuccessful, at least in terms of actual iron production. Early researchers too often undertook (or at least only formally reported on) limited test series (one or two attempts) and many concentrated far too much on slag, not on the production of metallic iron itself. (Nørbach, 1997; Nørbach, 1999) This was understandable on two counts. First, the nature of academic research does not normally lend itself to long drawn out series (especially with repeated ‘failures’ - in terms of actual iron production). Second, actual artefact blooms are at best uncommon, verging on rare. In this way the desired production outcome in terms of yields, consistency, even clues from shapes, was not clearly represented via archaeology (Pleiner, 2000). In contrast, what does survive, in massive quantities, is the waste product of glassy slags, presenting an obvious target for academic study. Importantly, in a working smelting furnace, the gross appearance and fluid behaviour of slag becomes far more important than its microstructure (See Figure 1a-c)!

The latter 1980’s through the early 1990’s saw some shift, primarily from outside the established academic circles. Increasingly, individuals with more practical backgrounds and a more general training in traditional / historic techniques, primarily working at European ‘open air’ museums, started attempting to duplicate historic processes. Generally, the intent was to investigate functional methods leading to iron production, often within a framework of public demonstrations. The acquiring of considerable experience was often more the result, rather than the conducting of formal experiments.

The long sequence of tests at Eindhoven, the Netherlands and Lejre, Denmark especially stand out (Nørbach, 1997). On the more academic side, the pioneering series by Peter Crew from the United Kingdom (North Wales) must certainly be noted (Crew and Crew, 2010). Gradually, some of this work would filter back into the academic literature, primarily through journal articles or conference proceedings. (Nørbach, 1997; Nørbach, 1999) The fact that so much of the practical work of iron production was in the hands of individuals who were not primarily academics, so not trained or tied into those formal reporting systems, most certainly influenced the ability to share results.

From the late 1990’s into the early 2000’s in North America, interest in bloomery iron appeared within the artisan blacksmith community. This was largely due to the work (and inspiration) of Lee Sauder and Skip Williams, based in Sauder’s studio workshop located in Lexington, Virginia (Sauder and Williams, 2002). A significant event was Michael McCarthy’s Early Iron Symposium in 2004, the first full scale gathering of those interested in small scale bloomeries on this side of the Atlantic, which would continue as an annual event in 2005 and 2006. Sauder afterwards hosted a series of workshops for fellow enthusiasts, all skilled artisan blacksmiths, annually from 2005 through 2011 (Markewitz, n.d.). The focus of these 10 to 14 day long workshop events was to determine, through repeated physical testing, just what individual factors would combine to create the best functioning small scale bloomeries. It is important to remember that the objective here was not the duplication of historic methods, although regional and historic prototypes were the starting inspiration for the test furnaces. The intent instead was to develop dependable methods of bloomery iron production, both in terms of high ore to bloom yields and overall quality of the resulting metal. This last aspect was an especially important consideration, as a reflection of possible historic processes. Certainly the desired end product of ancient iron makers was also a quality working bar, refined from the smelted bloom. The necessary second step of bloom to bar was rarely considered by early academic experimenters, an exception being the early work of Peter Crew (Crew and Crew, 2010) (See Figure 2).

Although some description of these practical working methods would be delivered into the academic realm, the primary impact would be through physical demonstrations and workshops lead by these experimenters for other artisan blacksmiths. (Sauder, 2000; Markewitz, n.d.) From about 2010 onwards, bloomery iron as a raw material attracted the interest of especially the bladesmithing community in the USA. Here the focus would remain on production and metal quality, not necessarily on historic method, or formal experimentation. The clearest example of this is the dominance of electrically powered blowers as the air supply. Because knife making is most commonly the final intention here, there has been considerable emphasis on the carbon content in the resulting working bars, especially over the last decade.

In Europe, the pattern had been largely different. Here most of those interested and working with bloomery iron has remained within the open-air museum / living history population. An increasing number of sites have attempted iron making, with prototypes drawn from their own individual historic / regional archaeology. (Wealden Iron Research Group, n.d.; Amersfoort, 2014; Vike, 2016; Ribe VikingeCenter, n.d.) Although success is still often measured in terms of yield and quality, the focus remains on historic elements. These efforts most commonly are framed as special events, almost always as demonstrations before the visiting public. There has also been the development of a number of regional and international symposiums in Europe, especially over the last decade. (International Iron Smelting Days, 2004; the Woodford Furnace Festival, 2018; Dymarki Festival of Archaeology, n.d.) As interest in bloomery iron as a material has filtered back into the blacksmithing community across Europe, increasingly the overall result is a productive blending of approaches, experiences, and skills seen at these events (See Figure 3).

As experimental archaeology, as a discipline, becomes more formalized, bloomery iron smelting is increasingly being used as an educational tool for the purposes of teaching ‘how to run an experiment’. In this case, the results, in terms of effective iron production, becomes less important.

Experiment or Experience?

Obviously, the current field of bloomery iron making is composed of individuals with a wide range of approaches, training, available resources, and objectives. As the field of experimental archaeology has gained increasing acceptance, and a new generation of researchers also increasingly values those with practical working experience, the initial gap between academic and artisan is also diminishing. Organizations such as EXARC (Europe) and ReARC (North America) have specifically laboured to bridge the divide between the ‘doer and the thinker’.

Those attempting bloomery iron smelting as a personal exploration almost always have huge limitations created by the absence of any institutional support:

- Although there are a number of clear (and accurate) guides to effective methods, written by experienced practitioners, these have been largely published on the internet, and academic bias often obscures the real value of these tutorials. (Sauder, 2000a; Hernandez, 2015; Markewitz, 2012)

- The cost of the raw materials required for building even a small furnace, to provide the needed fuel and ore for a single sequence, is considerable. Added to this is the physical labour required to prepare materials, build the furnace, then actually run a complete smelting cycle.1

- Self-supporting individuals are simply quite unlikely to have access to (or money to acquire) any but the simplest of recording instrumentation. Specialized tools may be imitated by less effective choices, simply because of availability or cost.2

- With no specific shared training, approach, or even intentions, there certainly has been no shared concept on what observations might be important, or how to document an individual experience. At best, there might be some notes taken, most commonly only intended for that individual to reproduce their own results.

- Many (if not most) individuals attempting to make bloomery iron, are not intending to share the fine details of their own experience, so may undertake very limited record keeping. There is a noticeable tendency to hold onto the ‘secret knowledge’ of hard earned methods by individuals, or at best small groups. A working blacksmith is most often focussed on making an unusual material, just as the first step in the larger creation process of a unique object. At best they may choose to report rough ore to bloom yields, perhaps approximate carbon content (particularly if, as many are in the USA, intending to make blades as the finished objects) (See Figure 4).

Taking the Measure

One important divergence in data recording is that American workers are most commonly using USA Imperial units (inches / pounds / gallons), when the rest of the world uses the Metric system. Although conversion of units is certainly possible, it is the opinion of the author that Metric units should be used as the standard language of science. There is also no standardized set of descriptive technical language. This is often aggravated when translations are made from the differing languages used by individual European experimenters. It is also the opinion of the author that English language terms should be adopted as the universal (at least for reports translated over into English). At the least, local ‘jargon’ terms should be clearly defined.3

Bloomery iron smelting is an extremely complex operation. There is a clear relationship between ore type, furnace material, slag control method, air supply, and fuel used. All contribute to the ‘best’ overall furnace design, physical process, and thus the results of the smelt. Just what might constitute a set of useful measurements and descriptions varies considerably between individual approaches. Regardless, there are dozens of variables, many with fairly tight tolerances, which can make the between success and failure. It is suggested here that there needs to be a minimum set of information recorded, if for no other reason than to allow the repetition of successful operations (or avoiding errors!), even for those more concerned with iron production.4 Those intending a more experimental approach most certainly need to record far more detailed descriptions of materials, equipment, and process to allow for useful comparisons to the work of other researchers.

What has become clear, over two decades of observation, is that at the current time there is no standardized set of expected measurements within a very wide spread community. The list of individual elements provided below is most certainly extensive, and perhaps in the view of some, over complex. It is also understood that some measurements may be beyond the capabilities of individuals (assessing ore iron content as the best example). Although it is not the intent of this paper to provide a primer on effective furnace design and operation, those individual factors that have proved most critical (in the experience of the author at least) are underlined. Those elements which may not apply to all are in italics.

One: Describing Intentions & Limitations

There is most obviously going to be a direct relationship between the person who is undertaking the smelting process, and what their intended end results might be. Someone mounting a public demonstration may be most concerned with information flow and even visual drama (and not actual iron production results). Those without significant institutional or economic support are unlikely to have access to instrumentation (ability to measure temperatures is a prime example). There are a number of aspects when describing both the process and the resulting iron that are very subjective, often based on previous smelting or associated metalworking experience. (A good example would be the ‘feel’ of a bloom as it is compacted, and how this helps define density or even carbon content). Those most focussed on the end result of converting ore through bloom into working bars is likely to be most concerned with overall bloom yields and metal ‘quality’ - and may have little interest in slag remains at all (See Figures 5 and 6).

| 1. | Event Type - may be one or more of:

|

| 2. | Prototype Reference - may be some combination of a specific historic period or regional / ‘ethnic’ type (an example: A ‘Medieval’ dated furnace from Iceland or one from Japan, would certainly be quite different!). With furnaces built for production purposes, again give some design reference as is possible. |

| 3. | Team Composition - number of people, roles undertaken |

| 4. | Previous Experience - some suggestion of the background of the team leader and the participants. (A group of working blacksmiths, a team of trained archaeologists, or a group of high school students - each would bring quite different skills and observational abilities to a smelt undertaking.) |

| 5. | Geographical Location (Remember to use a method that will be clear to an international reader.) |

| 6. | Physical Conditions - typically out of doors, so:

|

Two: Describing Construction and Smelting Materials

Considering here the materials added into the furnace during the smelting process. Care needs to be exercised to avoid purely local jargon (a common example is ‘bog iron ore’ = any ore found near water – see note 3). What pre-smelt preparation was the ore subjected to?

Simple descriptions like ‘clay’ need to be expanded, was that locally dug clay or commercially prepared, was the composition known, the sintering and importantly the melting temperatures? What species type of charcoal (or was some alternate fuel entirely used)?

A furnace build may be complex, and all the elements should be described. (An example would be a Norse Icelandic furnace, where the main structure is stacked grass turf strips, but also may have a thin ‘clay’ inner lining.) (Markewitz, 2007)

| 1. | Furnace Build:

|

| 2. | Tuyere (note that specific dimensions are listed with ‘Describing the Furnace):

|

| 3. | Ore:

|

| 4. | Fuel:

|

| 5. | Additional Materials Added to the Smelt – if used, consider:

|

Three: Describing the Furnace

A ‘problem’ here is that early classification systems to describe furnace types almost always centred on slag control methods, not the upper (working!) construction of the furnaces. This is somewhat understandable, as archaeology most commonly only uncovers the very base level of ancient furnaces. Both the position of the tuyere, and the total height of the shaft, as important as both are to effective function, are often completely unknowable. This is complicated by the many ‘traditional’, often regional or language based, terms in use. As experiment enriches archaeology, it is hoped some common terminology will emerge (See Figure 7).

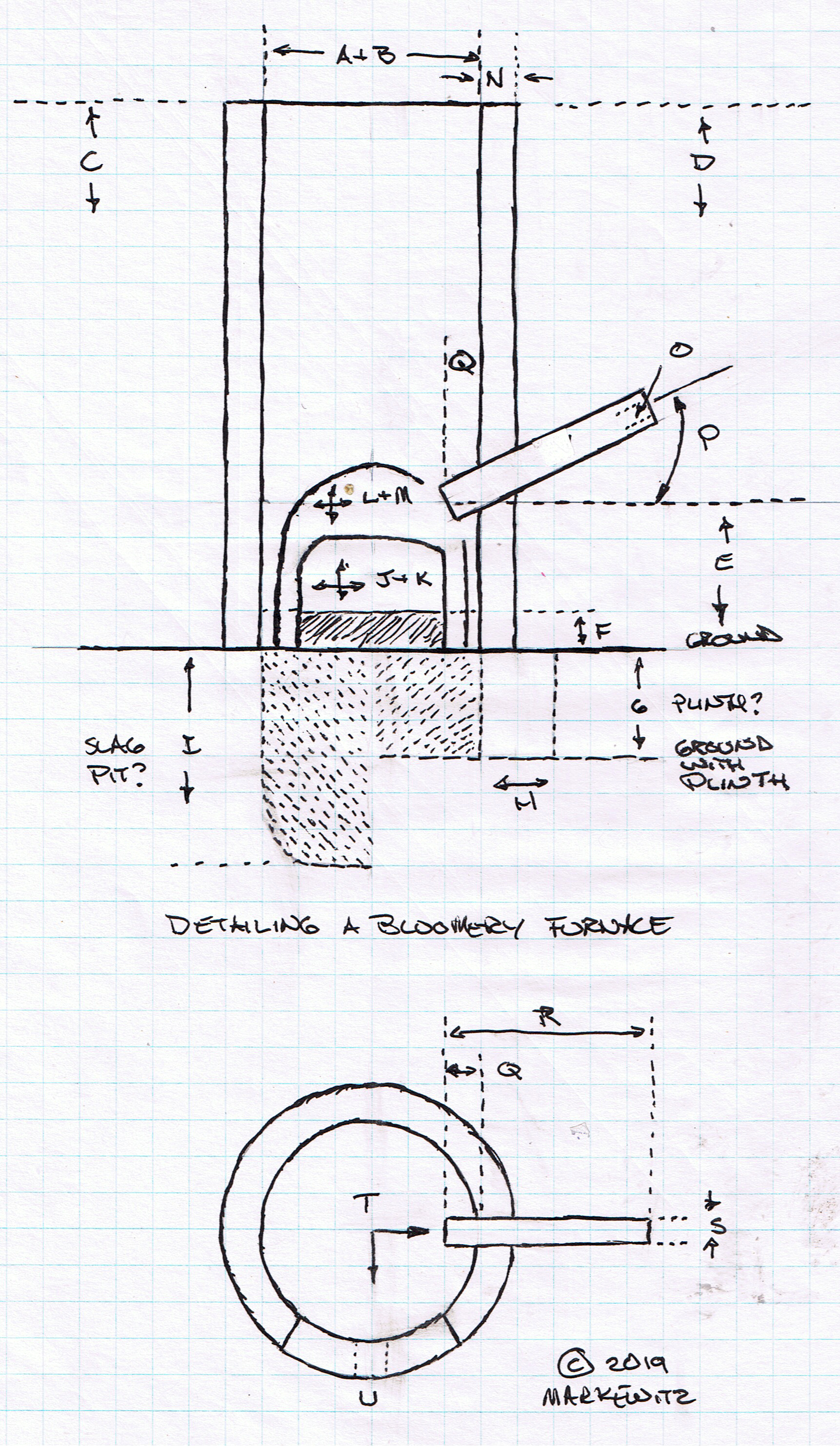

Fig 7. Detailing a bloomery furnace.

The following elements are illustrated, based around what the author defines as a simple ‘short shaft’ furnace, intended for slag tapping, and finally bottom extraction of the bloom. The drawing includes variables that also relate to alternate builds / methods (plinth, slagpit, ‘blow hole’).

| 1. | Furnace Design (letters refer to those shown in the illustration) A & B. Interior Diameter - measurement(s) at tuyere level, include diameter at top of furnace if different C. Total Height - from ground to top of furnace D. Stack Height - from centre of tuyere to top of furnace E. Base Depth - from centre tuyere to functional ‘hard’ bottom level of the furnace F. Packing / Soft Base Depth - (Being loose material added above ground level, changing the effective Base Depth.) (if used) G. Plinth (base blocks) Height - (Here a set of base blocks / stones raising the height of the furnace itself off the ground.) (if used) H. Plinth Wall Thickness - (if used) I. Slag Pit - (Here a hole below the furnace for draining slag into.) (if used)

J + K. Tap Arch - height and width (Here an opening specifically for draining liquid slag.) - (if used) L + M. Extraction Arch - height and width (Here a larger opening at the base of the furnace allowing for pulling the bloom out, if larger than above.) - (if used) N. Wall Thickness - (at top and bottom if varies) O. Tuyere Interior Diameter – (Here meaning the air pipe into the furnace.): taper measurements if applies P. Tuyere Insert Angle - measured from horizontal (plus pointing upwards or minus pointing downwards) Q. Distance Proud - from centre of tuyere tip, back to inner wall R. Tuyere Total Length S. Tuyere Outside Diameter (S - O = tuyere wall thickness) T. Offset - tuyere to extraction / tap arch - relative position of these elements (as degree of offset) U. Blow Hole - (Here a method where the tuyere is placed in front of a larger diameter hole cut into the furnace body) (if used):

|

| 2. | Air System:

|

Four: Describing Method

| 1. | Fuels:

|

| 2. | Ore Charges:

|

| 3. | Modifications as occur - (This may include any changes from the basic sequence, often because of needed repairs or equipment failures. Some very common undertakings are probing down the tuyere to clear slag blockages, and probing down from the top of the furnace to settle ‘hung up’ charcoal bridging internal gaps.)

|

| 4. | Slag Tapping (if used):

|

| 5. | Temperatures - (if measured - See detail below):

|

| 6. | Burn down:

|

| 7. | Extraction Method:

|

| 8. | Bloom Compaction (This most important when considering the condition of the final cold bloom.):

|

Five: Describing Results

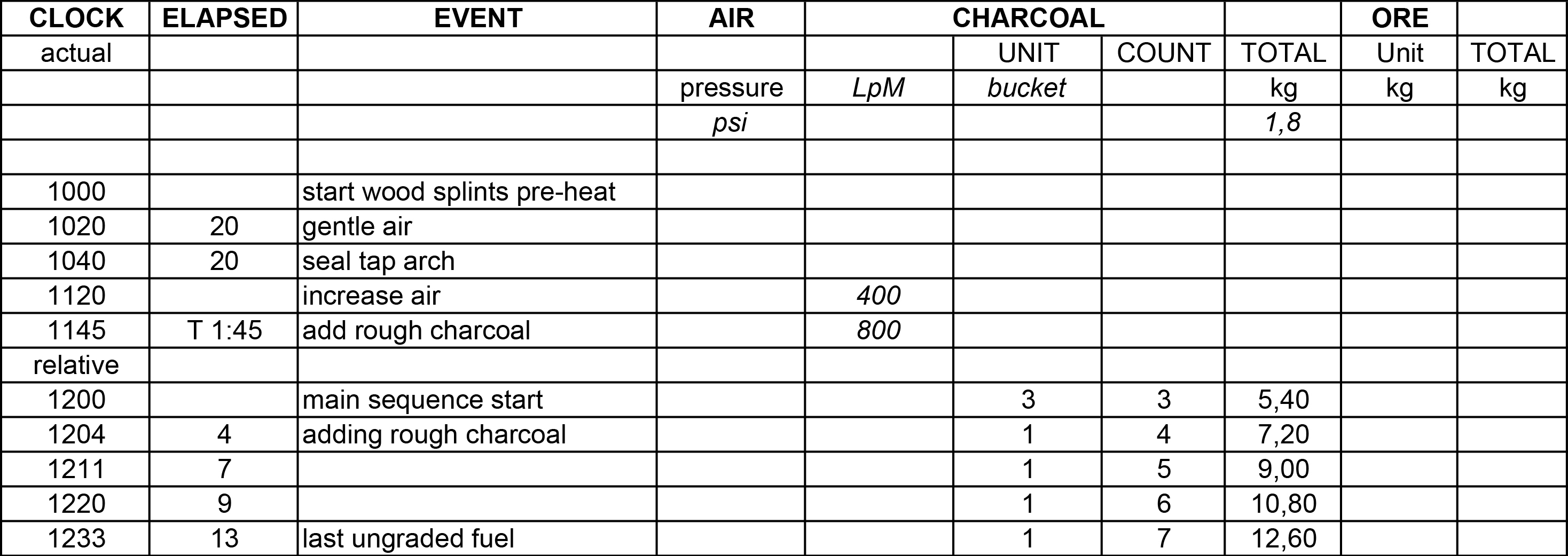

Fig 8. Sample of experiment record: Field notes into data frame

| 1. | Total Charcoal |

| 2. | Total Ore |

| 3. | Bloom (See detail below):

|

| 4. | Total Elapsed Time |

| 5. | Waste Produced (if collected):

|

| 6. | Furnace Erosion (as dimensions) (See Figure 9) |

Expanded Details - indicated above:

- Human Powered Air:

A large number of differing air systems were used historically. Unfortunately, bellows equipment is not well preserved archaeologically, and so at best the details of measurements are ‘educated guesses’.(Markewitz, 2008) Equipment designed for use at a blacksmith’s forge has consistently been proven to be less effective for iron smelting. Too often any ‘human powered bellows’ are considered ‘historically accurate’, even if the type chosen does not match the cultural set or time period. (The best example here would be a smelt labelled ‘Viking Age’ but using ‘Late Medieval’ Great Bellows, or ‘Chinese’ Box Bellows.)6

Generally, the use any human powered system requires a major organization in labour, and so may prove beyond the capabilities of many experimenters. An effective bellows of any type is also a fairly large and complex piece of equipment to physically make. It is primarily for these reasons that electrically powered blowers are often used. Additionally, there is a significant problem providing for consistent operation between changing workers, and the effect of fatigue on individual workers.

- Defining Air Volumes / Burn Rates:

There are a wide range of even electrically powered mechanisms used by individuals to deliver air into furnaces. Ideally, both flow and pressure would be measured, but the stated problem of instrumentation certainly is seen here. The data may be derived from instrumentation, after the event via video, even ‘eyeball estimation’, the type and method of recording and calculation should be described. It is suggested here that the standard for measuring air volumes should be litres per minute.

Defining volume is most problematic for those teams which use manual bellows – as there are huge variations in design, measurements, and operation rates (none of which are typically reported).

In the absence of instrumentation for almost all experimenters, the most practical method of judging effective air volumes over a smelting sequence is through measuring burn rates. (Sauder, 2000b) Most typical is recording a standard charcoal weight consumed against time. It has been (correctly) pointed out that in practice, burn rate is a more valuable measurement (and much easier to record) than air volumes. There is however no standardised way this is described. Although ‘kg per hour’ is often given in European reports, this is more a vague average (likely calculated after the experiment).

It is suggested that recording individual times between additions of standard weight will be most helpful in both detailing the progress of the reaction, plus serving as a guide to other researchers. Generally, the most useful indication is ‘minutes per kg’ (or commonly as ‘minutes per bucket’, with ‘bucket’ defined).7

- Temperatures:

Although directly recording temperatures during the smelting process may contribute information of scientific value, there are so many potential problems in gathering useful (even reliable) data - that for most experimenters, this aspect is unlikely to be attempted. The recording equipment and high temperature thermocouples ideally used are expensive. Simply accessing the interior of the furnace itself is sure to prove difficult. There are certain to be temperature gradients within the cross section body of the furnace. In fact, the previously discussed burn rates are functionally more important to be aware of during a smelting process itself (instrumentation is no substitute for practical experience). The same measure of charcoal, consumed too quickly, means too high internal temperatures, and most likely the formation of high carbon cast iron (which cannot be forged). Too slow a consumption is most likely to indicate some blockage in the established air flow, and in turn insufficient internal temperatures to effectively sustain the reduction to bloom formation processes.

Time would have been possible to assess even for ancient iron makers.8

- Describing Blooms:

Exactly just what constitutes an iron bloom is often so variable that this result is almost ‘in the eye of the beholder’. For those experimenters who have production as the objective, the obvious hard metallic ’nugget’ that remains after even a single consolidation set (mass hammered until temperature drops to a ‘red’ heat, fragile outer layers broken away) constitutes a bloom. It is important to differentiate that solid lump of iron from what might be better described as either ‘gromps’ or a ‘pre bloom mass’. (The second meaning here lacy filaments of iron within a primarily slag matrix remaining at the bottom of the furnace, essentially the initial stage of bloom formation.)

Although these fragments do indicate iron was produced, they physically cannot be forged down into workable iron bars. At best historically they might have been recovered for use in a second stage process9 (Espelund, 2013) It is the suggestion of the author that although ‘gromps’ should certainly be collected and recorded, their weight should not be included in calculation of production yields.

Determining relative quality of any bloom, in the absence of fairly elaborate (expensive) equipment is very much subjective and based on related experience. During the consolidation series, a well-practiced blacksmith can estimate, through sound and hammer feel, both the general solidity and also rough carbon content (hardness) of the metal. The carbon content can be also be at least roughly estimated by ‘spark testing’ over a cut interior surface (See Figure 10).10

Conclusion

Mounting even a single iron smelt is a large investment in time, labour and materials. Looking back over many experimental smelts, it is clear that there is a complex set of individual variables which combine to determine the best possible results. Changing more than two or three of those ideal aspects may result in poor returns, or even no significant iron production at all. What works for one local ore may not create the best yield or bloom quality with another.

In discussions between experienced and first-time iron makers, the two most common questions are: ‘Will this work? and ‘What went wrong?’. Core to understanding both of these questions is always ‘What did you do?’ Obviously for the scientific experimenter, recording as much available data as possible is critical. Often a full iron smelting sequence results in damage to (if not outright destruction) of the furnace when extracting the bloom. Subsequent reporting may have reduced value if full documentation was never made.

For the production iron maker, even small changes in method often result in large variations in yield or quality. In these situations, careful records are most likely to allow for better predictability over the intended bloom. It has been certainly demonstrated that recording details tends to help control technique - sloppy work tends to generate random results.

For both groups, recording the basic set up of the furnace, and the operating sequence undertaken, will best allow repeatability. The author would like to stress the immense value of photography, both the extensive use of still images, and where possible, short video segments. A huge amount of data can be easily recovered ‘after the event’ through the examination of images!

If sharing of knowledge is important, raw data must certainly be recorded – then hopefully made available to others. Re-invention of lost techniques is a long and difficult process, if an individual works in isolation.

Acknowledgements

The many references to both the continuing work, and private discussions with, Lee Sauder should certainly indicate the massive debt owed to him personally over 20 years of guidance, joint work, and friendship.

I would also like to thank my smelting partner Neil Peterson for his hard work taken together on experimental iron smelting over the last 20 years, and for his preview and edit of the draft of this paper.

Various members of the Dark Ages Re-Creation Company have contributed labour and taken part in many of the experiments and public demonstrations of bloomery iron smelting I have undertaken since 2002.

About the Author:

Darrell Markewitz from Ontario, Canada, has been a professional artisan blacksmith for over 30 years. Known as a specialist in the Viking Age, he has contributed to a number of major museum exhibits, including extensive work for Parks Canada at L’Anse aux Meadows NHSC. His interest in bloomery iron smelting started there in 2001, and his extensive practical and experimental research has included participation in a number of international projects and academic conferences over the last two decades. Past work is well documented on an (massive!) web site: www.warehamforge.ca/ironsmelting, plus on his blog: warehamforgeblog.blogspot.com

- 1Based on the ongoing series by the author, in Ontario Canada. One complete build and use cycle for a ‘short shaft’ furnace, 30 cm ID and 60 cm tall, 30 kg ore smelt. (in CDN $ / ‘work’ hours/ 2019) : Furnace materials - clay, sand = $40; Charcoal - 100 kg = $235; Ore - as red oxide ‘analog’ + $70; Furnace build = 6 hours; Fuel / Ore prep = 3 hours; Smelt = 27 hours (3 bodies x 9 + hours); Total: $350+ / 35 - 40 work hours (plus specialized tools)

- 2A clear example of this was the initial scorn placed on what academics called ‘Vacuum Cleaner Smelting’. Independent workers commonly used scrounged household vacuum cleaners, reversed, as air supply. Largely this was done because of the high cost (and difficulty in even finding) suitable powerful and reliable blowers. This had an important impact on record keeping on the early researchers in Denmark especially, where almost everyone was using virtually identical, small, aluminium housing, vacuum cleaners. So widespread was the use of this specific unit for air supply, few ever bothered to ever consider measuring or recording air volumes (‘Just use The blower…’ was a common refrain from smelters in that area).

- 3Two good examples: 1. European authors often use the term ‘coal’ to describe the fuel they are using. At least to North American readers, there is a big difference between wood ‘charcoal’ and rock mineral ‘coal’. The author has seen this kind of language perception problem come up many times inside discussions with fellow experimenters from across the world, especially if translations are involved. 2. Over the years, the author has seen the term ‘bog iron ore’ be applied to many quite different natural materials, with separate deposit mechanics and physical characteristics. At the extreme, ‘bog ore’ can be (and often is) used to describe ‘any iron bearing material deposited by water’. (At one occasion, a limonite rock ore, eroded and washed downstream hundreds of miles from its source, then recovered along an old river bank, was described as ‘bog ore’.) It is suggested here that a clear description of any ‘bog iron ore’ material, and its deposit method, be provided.

- 4Most especially important to first time workers in the field. Too often requests for advice on ‘what went wrong’ reveal that even the simplest measurements were never made. Many do not fully appreciate how what might appear small modifications or simple substitutions can drastically effect outcomes. In North America, one of the guiding concepts among the original ‘Early Iron Group’ was freely sharing of all information collected from personal experience and research.

- 5‘Gromps’ are defined here as pieces of combined slag and iron, with enough metal content to be magnetically sorted, but which have not remained solidly attached to the core bloom itself. These are pieces often struck off the bloom during the initial compaction phase. This material may also be removed later from the slag mass within the furnace. Even without the use of a magnet, usually the density of these fragments indicates their difference from slag.

- 6The clearest example of this is seen with those teams reporting use of ‘Viking Age’ bellows, where equipment is seen to range in design, size and operating method. All this when in truth there is not a single physical artifact of any bellows from that period, most certainly nothing ever recovered related to the iron smelting process.

- 7A working iron furnace will have individual consumption rates that undergo significant changes over the progress of a working smelt. The type of the furnace, and the type of the ore used may also effect these rates. The ratio of ore to charcoal most often varies over time for most experienced iron makers. It has been found in the author’s experience and observation that one of the best indications of the developing cycle inside the furnace is the elapsed time between individual standard charges.

- 8Several ‘historic’ types of time measurement were tested during the ‘Vinland’ experimental series, undertaken by the author’s team at L’Anse aux Meadows NHSC (Parks Canada) in 2012 (Markewitz, 2014). These included a ceramic pot filling with water, and chanting songs (which also had the added benefit of maintaining bellows pumping rhythm).

- 9Espelund has gone one step further, suggesting that there was an intentional two stage process, with a first smelting cycle used to create a ’semi refined product’, which then was later subjected to another full smelting effort to produce ‘higher quality ‘blooms (both in terms of size and density). It should be noted that the ‘quality’ of an individual bloom is most often highly subjective. It should be again remembered that the objective of ancient iron makers was not blooms, but (often standardized) working bars of iron. Consistency and ease of forging would have been far more important than the purely modern considerations of available carbon content.

- 10Care must be taken to assess the interior - and multiple areas across the surface. Past assessment of many blooms produced by the author has shown that the both the outer and inner portions, as well as the top and bottom surfaces, of a single bloom can vary considerably in carbon content. Estimates by ’Spark Testing’ is a method well known to working blacksmiths, but at best only provides a rough approximation of carbon content.

Country

- Canada

Bibliography

Amersfoort, J., 2014. Medieval Iron Production in Holland. [online] Available at: < https://www.youtube.com/watch?v=F3rjjpuhCLI > [Accessed: August 2020].

Crew, P. and Crew, S., 2010. 25 Years of Blooming Experiments - Perspectives & Prospects. In: HMS conference, West Dean College, 2-3rd Sept. 2010. [pdf] Available at: < https://www.academia.edu/4761369/25_years_of_blooming_experiments_perspectives_and_prospects_2010_? > [Accessed: August 2020].

Dymarki (Festival of Archaeology). [online] Available at: < http://dymarki.pl/dymarki-swietokrzyskie-nowa-slupia > [Accessed: August 2020].

Espelund, A., 2013. The evidence and the secrets of ancient bloomery ironmaking in Norway. Arketype Forlag, Norway.

Harrison, E., 2015. Iron, Turf and Bone, An explorative study into Viking Age Icelandic bloomery smelting and the effect of bone in iron smelting. DEd. University of Aberdeen.

Hernandez, J., 2015. Making Steel. [online, via the Internet WayBack Machine] Available at: < http://web.archive.org/web/20170429044813/http://jhbladesmith.com/craft/making-steel/ > [Accessed: August 2020].

International Iron Smelting Days. since 2004 [online] Available at: < https://sites.google.com/site/ironsmeltingdays/ > [Accessed: August 2020].

Markewitz, D., n.d. Experimental Iron Smelting [online] Available at: < http://www.warehamforge.ca/ironsmelting/index.html > [Accessed: August 2020].

Markewitz,D., 2007. Working towards an Icelandic Viking Age Smelt Based on the remains at Hals. [online] Available at: < http://www.warehamforge.ca/ironsmelting/HALS/index.html > [Accessed: August 2020].

Markewitz. D., 2008. Bellows Reconstruction – 2. [online] Available at: < https://warehamforgeblog.blogspot.com/2008/01/bellows-reconstruction-2.html > [Accessed: August 2020].

Markewitz, D., 2011. DARC at CanIRON 8 [online] Available at: < http://www.warehamforge.ca/ironsmelting/CanIRON8/Caniron.html > [Accessed: August 2020].

Markewitz, D., 2012.“But if you don’t get any IRON…” Towards an Effective Method for Small Iron Smelting Furnaces, EXARC Journal [online]. Available at: < http://exarc.net/issue-2012-1/ea/if-you-dont-get-any-iron-towards-effective-method-smalliron-smelting-furnaces > [Accessed: August 2020].

Markewitz, D., 2014. An Iron Smelt in Vinland - an experimental investigation. In: M. Cramer (ed.). Can These Bones Come to Life?, 2. Insights from Reconstruction, USA.. Also available online as pdf: < http://www.warehamforge.ca/ironsmelting/LAM/Smelting-Vinland-V3.pdf >.

Nørbach, L., ed., 1997. Early Iron Production - Archaeology, Technology and Experiments. Technical Report No. 3, Denmark, Historical-Archaeological Experiment Centre.

Nørbach, L., ed., 1999. Prehistoric and Medieval Direct Iron Smelting in Scandinavia and Europe. Denmark, Aarhus University Press.

Pleiner, R., 2000. Iron in Archaeology, The European Bloomery Smelters. Czech Republic, Archeologicky Ustav AV CR.

Ribe VikingeCenter, n.d., Extraction of Iron. [online] Available at: < http://ribevikingecenter.dk/en/learn-more/extraction-of-iron.aspx > [Accessed: August 2020].

Sauder, L., 2000a. The Basics of Bloomery Iron Smelting. In: The Anvil’s Ring. Artist Blacksmith Association of North America. Available as pdf at: < https://s3.amazonaws.com/images.icompendium.com/sites/eliz2406/sup/3694… > [Accessed: August 2020].

Sauder, L., 2000b. Smelt Diary for Smelts 21- 27. [online] Available at: < http://iron.wlu.edu/smelttables/21-27.html > [Accessed: January 2021].

Sauder, L. and Williams, S., 2002. A Practical Treatise on the Smelting and Smithing of Bloomery Iron, Historical Metallurgy, 36 (2). Available as pdf: < https://s3.amazonaws.com/images.icompendium.com/... > [Accessed: February 2021].

Vike, V., 2016. Fold Processing of Bog Iron. [online] Available at: < http://www.khm.uio.no/english/research/projects/langeid/project/iron-steel/folding/ > [Accessed: August 2020].

Wealden Iron Research Group, n.d., Experimental Ironmaking. [online] Available at: < http://www.wealdeniron.org.uk/experimental-bloomery-ironmaking > [Accessed: August 2020].

the Woodford Furnace Festival, Ireland, since 2018. [online] Available at: < http://www.furnacefestival.org > [Accessed: August 2020].